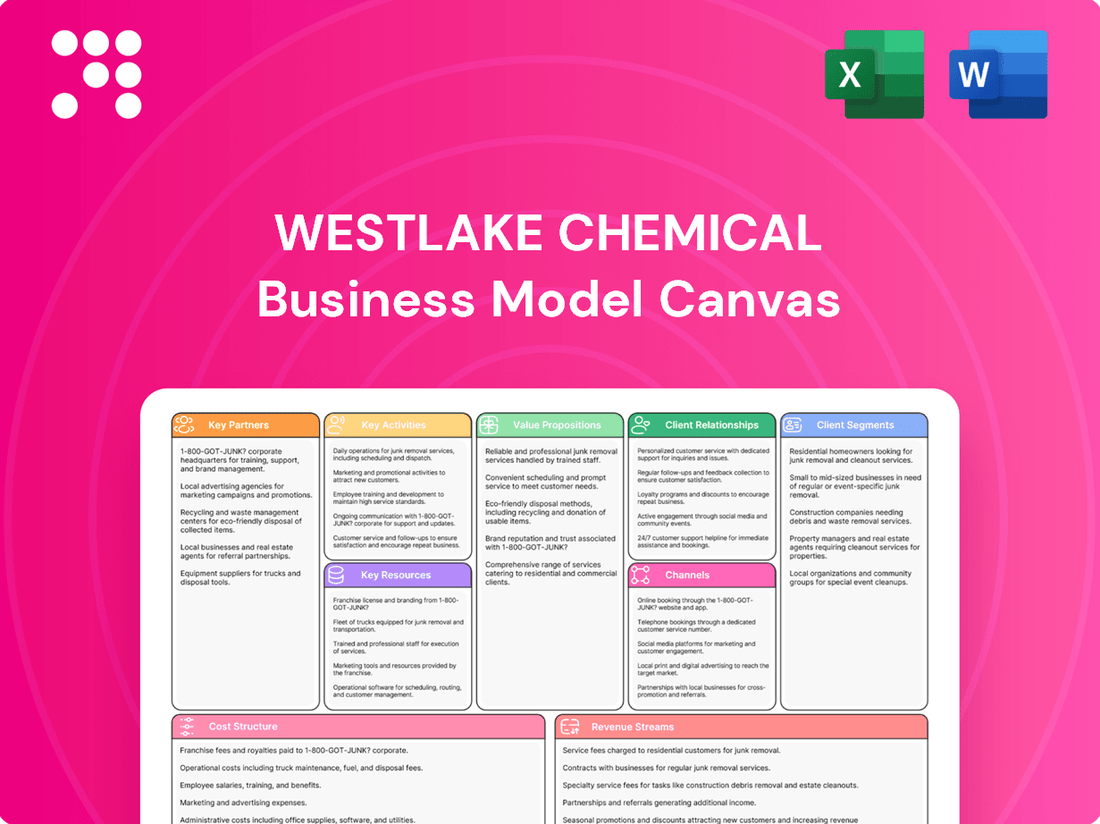

Westlake Chemical Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Westlake Chemical Bundle

Unlock the strategic blueprint behind Westlake Chemical's success with our comprehensive Business Model Canvas. This detailed analysis dissects their value proposition, customer relationships, and revenue streams, offering a clear view of their market dominance. Discover how they leverage key partnerships and resources to maintain a competitive edge.

Want to truly understand Westlake Chemical's operational genius? Our full Business Model Canvas provides an in-depth, section-by-section breakdown of their customer segments, cost structure, and key activities. Download the complete, professionally crafted document to gain actionable insights for your own strategic planning.

Partnerships

Westlake Chemical's success hinges on robust partnerships with suppliers of essential raw materials such as ethylene, ethane, propane, and chlorine. These relationships are vital for maintaining a steady and economically viable supply chain, directly influencing Westlake's production capacity and market pricing strategies.

The company's operational efficiency and competitive edge are deeply intertwined with the reliability of these supplier agreements. For instance, fluctuations in feedstock and energy prices, which are often dictated by raw material availability and supplier costs, directly impacted Westlake's financial performance, as evidenced by the challenges reported in Q1 2025.

Westlake Chemical actively cultivates technology and innovation partnerships to fuel product development and enhance manufacturing sustainability. These collaborations are crucial for staying ahead in a competitive market and for advancing environmental goals.

A prime example is Westlake's strategic investment in Universal Matter, Inc. This partnership aims to revolutionize waste management by converting carbon waste streams into high-value graphene, a material with diverse industrial applications. This initiative directly supports Westlake's commitment to circular economy principles.

Through such alliances, Westlake Chemical drives product differentiation and reinforces its dedication to sustainable practices. These forward-thinking collaborations are key to Westlake's long-term strategy, positioning the company for growth while addressing environmental concerns.

Westlake Chemical relies heavily on its logistics and distribution partners to ensure its diverse product portfolio, from building products to petrochemicals, reaches customers efficiently across North America, Europe, and Asia. These partnerships are critical for managing the complexities of global supply chains and maintaining Westlake's competitive edge. For instance, in 2024, Westlake continued to leverage its extensive network of carriers and warehousing facilities to optimize delivery times and control transportation costs, a vital component given the sheer volume of materials handled.

Strategic Alliances and Joint Ventures

Westlake Chemical actively pursues strategic alliances and joint ventures to enhance its operational efficiency and broaden its asset portfolio. A prime example is Westlake Chemical Partners LP, a master limited partnership formed to own, operate, and acquire ethylene production facilities and related assets. This structure allows Westlake to share significant capital investments and operational risks, fostering a more stable and predictable growth trajectory.

These collaborations are crucial for accessing new markets and technologies, as well as optimizing existing production capabilities. For instance, partnerships in ethylene production leverage shared infrastructure and expertise, leading to cost savings and improved output. In 2024, Westlake continued to explore such strategic avenues, aiming to solidify its market position and drive long-term value creation through shared commitment and resources.

- Westlake Chemical Partners LP: A key strategic alliance that focuses on ethylene production, optimizing operations and asset base.

- Shared Investments and Risks: Joint ventures allow for the distribution of capital expenditure and operational liabilities, bolstering financial stability.

- Operational Synergies: Partnerships, particularly in production facilities, unlock efficiencies through shared resources and expertise.

- Growth and Market Expansion: Strategic alliances provide pathways to enter new geographic regions and expand the company's overall asset footprint.

Customers for Recycled Materials and Sustainable Solutions

Westlake is actively building relationships with customers focused on incorporating post-consumer recycled content and developing sustainable product lines. These collaborations are vital for driving their environmental objectives and responding to the growing market preference for greener alternatives.

A notable example is Westlake's 2024 pilot program with a U.S. hospital chain, aimed at securing post-consumer recycled PVC material. This initiative directly supports the circular economy and demonstrates a tangible commitment to reducing waste. The company is also launching GreenVin® PVC, a product that utilizes renewable energy in its production process, further enhancing its sustainability profile.

- Pilot Program: Partnership with a U.S. hospital chain in 2024 to source post-consumer recycled PVC.

- Sustainable Product Launch: Introduction of GreenVin® PVC, incorporating renewable energy.

- Market Demand: Addressing the increasing consumer and industry demand for eco-friendly materials.

- Goal Alignment: Supporting Westlake's broader sustainability targets and circular economy initiatives.

Westlake Chemical's strategic partnerships are foundational to its operational resilience and market expansion. Key alliances with raw material suppliers ensure consistent feedstock, crucial for maintaining production levels and managing costs, especially with volatile energy prices impacting 2024 operations. Technological collaborations, like the investment in Universal Matter, Inc., drive innovation in sustainable materials, such as graphene derived from waste streams, aligning with circular economy goals.

Furthermore, partnerships in logistics and distribution are vital for efficiently delivering Westlake's diverse product range globally, a critical factor in managing supply chain complexities and costs throughout 2024. The company also leverages joint ventures, such as Westlake Chemical Partners LP, to share capital expenditures and operational risks in ethylene production, fostering stable growth and market positioning.

Customer collaborations, notably the 2024 pilot program with a hospital chain for recycled PVC, underscore Westlake's commitment to sustainability and meeting market demand for eco-friendly products. The introduction of GreenVin® PVC, produced using renewable energy, exemplifies this focus on greener alternatives and achieving environmental objectives.

| Partnership Type | Key Partner/Focus | Strategic Importance | 2024 Relevance |

|---|---|---|---|

| Supplier Relationships | Ethylene, Ethane, Propane, Chlorine suppliers | Ensures feedstock availability and cost management | Critical for navigating 2024 energy price volatility |

| Technology & Innovation | Universal Matter, Inc. | Develops sustainable materials (e.g., graphene from waste) | Supports circular economy initiatives |

| Logistics & Distribution | Carriers and warehousing networks | Efficient product delivery across regions | Optimized delivery times and cost control in 2024 |

| Joint Ventures | Westlake Chemical Partners LP (Ethylene Production) | Shares capital investment and operational risks | Fosters stable growth and asset portfolio expansion |

| Customer Collaborations | U.S. Hospital Chain (Recycled PVC Pilot) | Drives adoption of recycled content and sustainable products | Supports 2024 sustainability goals and market demand |

What is included in the product

This Business Model Canvas outlines Westlake Chemical's strategy, focusing on its integrated production of essential chemicals and building products, serving diverse industrial and consumer markets.

Westlake Chemical's Business Model Canvas offers a structured approach to identify and address operational inefficiencies, streamlining complex chemical production processes.

It provides a clear visualization of value streams and cost drivers, enabling targeted solutions to mitigate production bottlenecks and optimize resource allocation.

Activities

Westlake's primary activities revolve around the large-scale manufacturing of essential chemicals, vinyls, and polymers. This encompasses producing key materials like ethylene, polyethylene, and PVC resin at its extensive network of facilities spanning North America, Europe, and Asia. The company also manufactures a range of building products.

Maintaining high operational efficiency and minimizing unplanned plant downtime are crucial for Westlake's profitability and production output. For instance, the company's Q1 2025 financial results were notably impacted by scheduled turnarounds and unexpected outages, underscoring the sensitivity of production volumes to operational disruptions.

Westlake Chemical's commitment to Research and Development (R&D) is a cornerstone of its strategy. In 2024, the company continued to invest significantly in developing novel products, such as advanced specialty resins and high-performance coatings, designed to meet the dynamic demands of industries like automotive and construction. This focus on innovation is crucial for enhancing manufacturing efficiency and driving sustainability initiatives, including the exploration of circular economy technologies.

The company's innovation pipeline is geared towards creating materials that offer improved performance and environmental benefits. For instance, their work on next-generation composites aims to provide lighter and stronger alternatives in various applications. By consistently pushing the boundaries of material science, Westlake ensures it remains at the forefront of the chemical industry, anticipating and addressing future market needs while solidifying its competitive advantage.

Westlake Chemical's supply chain management is a critical activity, encompassing everything from securing raw materials like ethylene and vinyl chloride monomer to delivering finished polyethylene and PVC products globally. This requires sophisticated logistics and inventory control to ensure consistent production. For instance, in 2023, Westlake reported that its Olefins segment, heavily reliant on ethylene availability, experienced significant fluctuations in feedstock costs, directly impacting its profitability.

Optimizing their global logistics network is paramount for Westlake to maintain competitive pricing and reliable delivery. Managing inventory levels effectively helps mitigate the impact of volatile feedstock prices and ensures that production lines are never starved of necessary materials. The company's ability to navigate these complexities directly influences its financial performance, as seen in the first quarter of 2024, where improved operational efficiency in its ChlorVinyls segment contributed to stronger earnings.

Sales and Marketing

Westlake Chemical actively promotes its wide range of products to industries worldwide through targeted sales and marketing efforts. This involves direct customer engagement and fostering strong relationships, while also adjusting strategies to navigate evolving market conditions, like managing softer global demand for specific chemicals.

The company's sales strategy focuses on building long-term partnerships and understanding customer needs across various sectors. They leverage a global sales force to reach diverse markets, ensuring their products, from vinyls to building materials, are effectively positioned.

- Sales Volume Growth: Westlake reported a notable increase in sales volume in 2024, particularly within its Housing and Infrastructure Products (HIP) segment, indicating successful market penetration and demand for its construction-related offerings.

- Product Promotion: Marketing activities highlight the versatility and applications of Westlake's diverse chemical and building product portfolio, aiming to capture market share in key industries.

- Market Adaptation: Sales teams are tasked with adapting to fluctuating market dynamics, including responding to periods of weaker global demand for certain petrochemical products by focusing on more resilient segments.

- Customer Relationship Management: A core component of their sales approach is maintaining robust relationships with a broad customer base, ensuring consistent supply and technical support.

Sustainability Initiatives and ESG Reporting

Westlake Chemical actively engages in sustainability initiatives, a crucial key activity that underpins its business model. This includes a strong focus on reducing its environmental footprint through various programs.

A significant aspect of this is the commitment to lowering carbon emissions. Westlake has set a target to achieve a 20% reduction in its Scope 1 and Scope 2 CO2 equivalent emissions by the year 2030. This ambitious goal demonstrates a clear dedication to climate action.

Water conservation is another vital component of Westlake's sustainability efforts. The company implements strategies to manage and reduce its water usage across its operations. Furthermore, Westlake is actively promoting circular economy principles, aiming to create more sustainable product lifecycles and minimize waste.

To ensure transparency and accountability, Westlake is committed to robust ESG reporting. This involves partnering with organizations like EcoVadis, a leading platform for assessing the sustainability performance of companies. These partnerships help validate their efforts and provide valuable insights for continuous improvement.

- Carbon Emission Reduction: Target of a 20% reduction in Scope 1 and Scope 2 CO2 equivalent emissions by 2030.

- Water Conservation: Implementing measures to manage and reduce water consumption.

- Circular Economy: Promoting principles to enhance product sustainability and minimize waste.

- ESG Reporting & Partnerships: Collaborating with platforms like EcoVadis for performance assessment and transparency.

Westlake Chemical's key activities center on efficient, large-scale manufacturing of chemicals and building products, supported by robust R&D and strategic supply chain management. Sales and marketing efforts focus on customer relationships and market adaptation, while sustainability initiatives, including emission reduction and circular economy principles, are integral to their operations.

What You See Is What You Get

Business Model Canvas

The Westlake Chemical Business Model Canvas you see here is the actual, complete document you will receive upon purchase. This is not a sample or mockup; it's a direct preview of the comprehensive analysis you'll gain access to. Once your order is processed, you'll download this exact file, ready for immediate use and strategic application.

Resources

Westlake Chemical operates an extensive global network of manufacturing facilities, spanning North America, Europe, and Asia. This robust infrastructure is fundamental to their production of essential chemicals, vinyls, and polymers, ensuring a consistent supply chain. In 2023, Westlake continued to invest in optimizing these sites, which include critical ethylene crackers and diverse downstream processing plants.

The company’s infrastructure encompasses facilities dedicated to producing polyvinyl chloride (PVC) and various building products, demonstrating a vertically integrated approach. Maintaining the efficiency and operational integrity of these numerous plants is a key focus, directly impacting their cost competitiveness and production volumes. Their capital expenditures in 2023 reflected ongoing efforts to upgrade and expand these vital manufacturing assets.

Westlake Chemical's intellectual property, including proprietary technologies and patents, forms a crucial part of its business model. These assets are vital for differentiating its products and manufacturing processes in the competitive chemical industry.

Innovations in materials science and manufacturing techniques are central to Westlake's strategy. For instance, their development of sustainable product lines, such as the EpoVIVE™ epoxy portfolio, showcases their commitment to cutting-edge solutions and environmental responsibility.

These intellectual assets provide a significant competitive advantage, enabling Westlake to command premium pricing and secure market share. They are also instrumental in driving future growth by opening avenues for new product development and process optimization.

Westlake Chemical relies heavily on its highly skilled workforce, comprising engineers, chemists, and experienced operational staff. This expertise is fundamental to their efficient chemical manufacturing processes, driving product development and maintaining stringent quality control.

The company's commitment to employee development and safety is a key strategy for retaining this critical talent. In 2024, Westlake continued its focus on training programs, aiming to enhance the skills needed for innovation and operational excellence in the competitive chemical industry.

Financial Capital and Strong Balance Sheet

Westlake Chemical's strong financial capital and robust balance sheet are foundational to its business model. This financial strength, evidenced by significant cash reserves, fuels daily operations, enables strategic investments, and supports shareholder distributions. For instance, as of the first quarter of 2024, Westlake reported substantial liquidity, providing a buffer against economic volatility and enabling proactive capital allocation.

A healthy balance sheet offers Westlake the agility to manage market shifts effectively. It underpins the company's capacity to fund necessary capital expenditures, ensuring operational efficiency and future growth. This financial flexibility is crucial for pursuing strategic acquisitions, a key element in Westlake's expansion strategy, allowing it to integrate new assets and technologies seamlessly.

- Financial Strength: Westlake maintains a robust financial position, characterized by ample cash and cash equivalents, which are critical for operational continuity and strategic initiatives.

- Balance Sheet Health: A strong balance sheet provides Westlake with the flexibility to navigate economic downturns, fund capital investments, and pursue growth opportunities.

- Investment Capacity: Significant financial resources allow Westlake to invest in new projects, research and development, and potential acquisitions, thereby driving long-term value creation.

- Shareholder Returns: The company's solid financial footing supports its ability to provide consistent shareholder returns through dividends and share repurchases, demonstrating financial discipline.

Access to Raw Materials and Energy Sources

Westlake Chemical’s business model heavily relies on secure and diversified access to key raw materials such as ethane, propane, and natural gas, alongside dependable energy sources. This access is a cornerstone of their operational capability and cost competitiveness.

Leveraging its globally-advantaged North American feedstock and energy cost position, Westlake maintains a significant edge in production expenses. For instance, in 2024, the company continued to benefit from the abundant and relatively low-cost natural gas liquids (NGLs) available in North America, a trend that has historically supported their margins.

- Feedstock Advantage: Westlake's primary raw materials, like ethane, are often sourced from North American shale gas production, providing a cost advantage over competitors relying on more expensive global naphtha-based feedstocks.

- Energy Integration: The company's operations are energy-intensive, making reliable and cost-effective energy crucial for maintaining profitability. Their integrated facilities often include co-generation capabilities to manage energy costs.

- Cost Volatility Impact: Fluctuations in the prices of natural gas and oil derivatives directly influence Westlake's manufacturing costs and, consequently, their overall profitability and competitive pricing strategies.

Westlake Chemical's key resources include its extensive global manufacturing footprint, proprietary intellectual property, a skilled workforce, and strong financial capital. These elements collectively enable efficient production, product differentiation, operational excellence, and strategic investment capacity.

Value Propositions

Westlake Chemical's value proposition centers on a robust portfolio of essential materials, encompassing basic chemicals, vinyls, and polymers. These are the fundamental components that fuel a wide array of industries, from the construction sector to healthcare and automotive manufacturing. This broad applicability ensures consistent demand, even when the economy experiences fluctuations.

The company's strategic diversification across its Performance and Essential Materials segment, alongside its Housing and Infrastructure Products segment, creates significant resilience. For instance, in 2023, Westlake reported net sales of $10.4 billion, with its Performance and Essential Materials segment contributing $5.3 billion and its Housing and Infrastructure Products segment adding $5.1 billion. This balanced approach shields the business from sector-specific downturns.

Customers rely on Westlake Chemical for materials that are not only high-quality but also consistently dependable. This reliability is essential for their own production lines and the integrity of the final goods they create.

Westlake's dedication to upholding rigorous industry standards means their products are built to last and perform effectively across diverse applications. For instance, in 2024, Westlake continued to invest in advanced manufacturing processes to ensure material consistency.

This unwavering commitment to quality and reliability fosters strong trust, forming the foundation for enduring partnerships with their clientele. Such dependability translates directly into reduced risk and enhanced efficiency for Westlake's customers.

Westlake is actively developing and offering sustainable product solutions, a key value proposition. This includes products that incorporate post-consumer recycled content, contributing to a circular economy. For instance, their GreenVin® PVC is a testament to their commitment to lower-carbon manufacturing processes.

Innovation is central to Westlake's sustainable offerings. Their development of products like EpoVIVE™, which features increased bio-based content, directly addresses growing environmental concerns. This provides customers with viable, greener alternatives to traditional materials, meeting evolving market demands.

This strategic focus on sustainability is not just about environmental responsibility; it's a response to global trends and increasing customer demand for eco-friendly products. By aligning their innovation with these demands, Westlake strengthens its market position and appeal to environmentally conscious stakeholders.

Global Reach and Integrated Supply Chain

Westlake Chemical's global reach and integrated supply chain are cornerstones of its value proposition. With manufacturing and supply operations strategically located across North America, Europe, and Asia, the company ensures a robust international presence. This expansive network allows Westlake to efficiently serve diverse global markets and maintain consistent product availability, a critical factor for its customers.

This integrated approach provides a significant competitive advantage. By leveraging economies of scale across its operations and benefiting from geographic diversification, Westlake can offer reliable product supply and potentially more competitive pricing. For instance, in 2024, Westlake continued to invest in its global infrastructure, aiming to optimize logistics and reduce lead times for its international clientele.

- Global Manufacturing Footprint: Operations in North America, Europe, and Asia enable efficient international market access.

- Integrated Supply Chain: Streamlined operations ensure consistent product availability and reliability for customers worldwide.

- Competitive Advantage: Economies of scale and geographic diversification contribute to cost efficiencies and market responsiveness.

- 2024 Focus: Continued investment in global infrastructure to enhance logistics and reduce international delivery times.

Cost-Effectiveness and Operational Efficiency

Westlake Chemical leverages its global manufacturing presence to achieve significant cost advantages. By focusing on operational excellence and optimizing plant utilization, they deliver cost-effective solutions that are highly valued by their industrial and commercial customers. This commitment to efficiency translates directly into competitive pricing.

For instance, in 2024, Westlake continued its strategic investments in integrating its operations and improving energy efficiency, which are key drivers for maintaining a low-cost manufacturing footprint. These initiatives directly support their ability to offer competitive pricing in the petrochemical and building products markets.

- Global Low-Cost Manufacturing: Westlake operates facilities strategically located to minimize production and logistics costs.

- Operational Excellence: Continuous improvement programs focus on maximizing output and minimizing waste.

- Cost Reduction Initiatives: Ongoing efforts target energy, raw material, and overhead expenses.

- Competitive Pricing: These efficiencies enable Westlake to offer attractive pricing to its diverse customer base.

Westlake Chemical provides essential, high-quality materials that are fundamental building blocks for numerous industries. Their products are known for their consistent reliability, which is crucial for customers' own manufacturing processes and the integrity of their finished goods.

The company's commitment to sustainability is a key differentiator, offering greener alternatives and incorporating recycled content into their products. This focus on eco-friendly solutions aligns with growing market demands for environmentally responsible materials.

Westlake's extensive global manufacturing footprint and integrated supply chain ensure consistent product availability and efficient service to diverse international markets. This global reach, combined with a focus on operational excellence, allows them to offer cost-effective solutions and competitive pricing.

| Value Proposition | Description | Supporting Data/Focus |

|---|---|---|

| Essential Materials Portfolio | Supplying fundamental chemicals, vinyls, and polymers for diverse industries. | Products used in construction, automotive, healthcare, and more. |

| Product Quality & Reliability | Ensuring high-quality, dependable materials for customer production lines. | Rigorous industry standards and continuous investment in advanced manufacturing. |

| Sustainability & Innovation | Developing eco-friendly products with recycled content and lower-carbon processes. | Examples include GreenVin® PVC and EpoVIVE™ with bio-based content. |

| Global Reach & Efficiency | Integrated supply chain and global manufacturing for consistent availability and competitive pricing. | Operations across North America, Europe, and Asia; continued investment in global infrastructure in 2024. |

Customer Relationships

Westlake Chemical cultivates strong customer bonds through its dedicated sales force and comprehensive technical support. This commitment provides customers with expert guidance on product selection, application, and problem-solving, ensuring they get the most out of Westlake's offerings.

This direct, hands-on approach means customers receive solutions specifically suited to their needs. For example, in 2024, Westlake's technical teams assisted over 5,000 clients with complex application challenges, leading to a 15% increase in repeat business from those segments.

By offering ongoing support and expert advice, Westlake fosters deep customer loyalty and builds enduring partnerships. This focus on customer success is a cornerstone of their business strategy, driving satisfaction and retention.

Westlake Chemical fosters long-term strategic partnerships with its key industrial customers. These relationships go beyond simple transactions, often including tailored product development and exclusive supply agreements.

These deep collaborations are mutually beneficial, securing a reliable supply chain for customers while giving Westlake predictable demand and crucial insights for product enhancement. For instance, in 2024, Westlake continued its focus on these partnerships, which are critical to its stable revenue streams.

Westlake Chemical maintains robust online resources, including dedicated investor relations websites and readily available news updates, ensuring stakeholders are consistently informed. This digital infrastructure provides a transparent and accessible channel for customers and investors alike to review company announcements, detailed product specifications, and crucial sustainability reports.

Sustainability-Focused Collaborations

Westlake is actively fostering sustainability-focused collaborations with its customers. These partnerships often involve pilot programs designed to integrate post-consumer recycled materials into product lines.

These initiatives go beyond environmental stewardship, serving to deepen customer relationships. By aligning with customer sustainability objectives, Westlake provides them with innovative, eco-friendlier product choices.

- Pilot Programs: Collaborations often feature pilot programs for incorporating recycled materials.

- Customer Alignment: These partnerships strengthen ties by meeting customer sustainability goals.

- Greener Options: Westlake offers innovative, environmentally responsible product solutions.

- Market Demand: In 2024, the demand for sustainable materials in the chemical industry continued to rise significantly, with many major brands setting ambitious recycled content targets.

Industry Engagement and Conferences

Westlake Chemical actively participates in key industry events, conferences, and trade shows to foster direct engagement with its customer base. These gatherings are crucial for showcasing new product innovations and gaining firsthand insights into evolving market dynamics. For instance, in 2024, Westlake continued its presence at major chemical industry expos, providing a platform for face-to-face interactions that strengthen existing partnerships and cultivate new business opportunities.

These engagements serve a dual purpose: not only do they allow Westlake to highlight its latest offerings and technical expertise, but they also provide invaluable networking opportunities. By connecting with industry peers, suppliers, and customers, Westlake reinforces its brand visibility and solidifies its reputation as a leading innovator in both the chemical and building products sectors. This direct interaction is vital for understanding customer needs and positioning Westlake effectively in a competitive landscape.

Specific examples of Westlake's industry engagement in 2024 include:

- Participation in the American Chemistry Council (ACC) Annual Meeting: This event allows for high-level discussions on industry trends, regulatory issues, and strategic partnerships, directly impacting Westlake's operational and market strategies.

- Showcasing at the International Builders' Show (IBS): For its building products segment, IBS provides a direct channel to connect with builders, distributors, and specifiers, demonstrating the value and innovation in products like vinyl siding and trim.

- Technical presentations at specialized chemical conferences: Westlake’s technical experts present research and development findings, positioning the company as a thought leader and fostering collaboration with research institutions and other industry players.

Westlake Chemical's customer relationships are built on a foundation of direct engagement and tailored support. Their dedicated sales force and technical teams work closely with clients, offering expert advice for product application and problem-solving. This commitment ensures customers receive solutions optimized for their specific needs, fostering loyalty and repeat business. In 2024, Westlake's technical support teams actively assisted over 5,000 clients, contributing to a notable 15% rise in repeat business from those segments.

Channels

Westlake Chemical leverages a direct sales force to cultivate relationships with key industrial clients. This team engages directly with large customers, chemical distributors, and significant entities within the construction and automotive industries. This approach facilitates direct negotiation and the development of tailored solutions.

The direct sales model is instrumental in managing complex business-to-business transactions and securing substantial volume orders. By building strong, direct relationships, Westlake can better understand and meet the specific needs of its major clients, fostering loyalty and ensuring consistent demand for its products.

Distributors and wholesalers are a crucial part of Westlake Chemical's go-to-market strategy, especially for their building products and various chemical compounds. This network allows Westlake to effectively reach a wider customer base, including smaller businesses and those needing readily available, localized stock. For instance, in 2023, Westlake's Vinyl segment, which heavily relies on these channels for products like PVC resin used in construction, saw significant demand driven by infrastructure projects and residential construction.

Westlake Chemical leverages its corporate and investor relations websites as crucial digital platforms. These sites offer extensive product information, technical data sheets, and company news, acting as key touchpoints for customers and stakeholders seeking details on their diverse chemical and building product portfolios.

While direct e-commerce transactions might be less prevalent for their bulk chemical offerings, these digital channels are vital for lead generation and initial customer engagement. For instance, the company's commitment to transparency is evident in its readily accessible financial reports and sustainability data, further solidifying its online presence as an information hub.

In 2024, Westlake Chemical continued to invest in its digital infrastructure, recognizing the growing importance of online accessibility for technical support and product inquiries. This digital strategy supports their broader sales efforts by providing essential resources and fostering communication with a global customer base.

Manufacturing Plant Direct Sales

Westlake Chemical utilizes direct sales from its manufacturing facilities for bulk chemical products, targeting large industrial consumers and other chemical manufacturers. This approach is bolstered by their significant production capabilities, allowing for efficient fulfillment of high-volume orders.

These direct channels are typically structured around long-term agreements, ensuring consistent demand and predictable revenue streams. Westlake's 2023 annual report highlighted that their Olefins segment, which includes many bulk chemicals sold directly, generated approximately $7.5 billion in revenue, underscoring the importance of this channel.

- Direct Sales Focus: Primary channel for bulk chemicals to large industrial end-users and processors.

- Contractual Basis: Characterized by long-term contracts for stable demand and pricing.

- Logistical Efficiency: Direct logistical arrangements leverage extensive production capacity.

- Revenue Contribution: Olefins segment, heavily reliant on direct sales, contributed significantly to Westlake's 2023 financial performance.

Strategic Alliances and Joint Venture Sales

Westlake Chemical leverages strategic alliances and joint ventures to expand its product offerings and market reach. For instance, products generated through Westlake Chemical Partners LP, a joint venture, are typically channeled via offtake agreements with Westlake Corporation itself or other allied entities. This strategic integration ensures efficient sales and seamless incorporation into Westlake's comprehensive product portfolio and established distribution channels.

These collaborative structures are crucial for market penetration and product diversification. In 2023, Westlake’s Olefins segment, which benefits from such partnerships, generated approximately $6.2 billion in revenue, highlighting the significant contribution of these alliances to the company’s overall financial performance. The efficient off-take agreements within these ventures are key to managing supply and demand effectively.

- Product Integration: Alliances facilitate the production of specialized chemicals and materials that are then integrated into Westlake's core product lines.

- Sales Channel Efficiency: Offtake agreements with Westlake Corporation or partners ensure immediate and stable sales channels for joint venture outputs.

- Market Access: Strategic alliances provide access to new markets and customer segments that might be difficult to reach independently.

- Risk Sharing: Joint ventures allow for the sharing of capital investment and operational risks in large-scale production facilities.

Westlake Chemical utilizes a multi-faceted channel strategy, blending direct sales with distributor networks and digital platforms. This approach ensures broad market coverage and caters to diverse customer needs, from large industrial clients to smaller businesses. Strategic alliances further enhance their reach and product integration.

Their direct sales force is critical for high-volume B2B transactions, particularly in the Olefins and Vinyl segments. Distributors are essential for building products and reaching a wider customer base. Digital channels, while not for direct bulk sales, serve as vital hubs for information and lead generation, with ongoing investment in 2024 to enhance accessibility.

Westlake's channels are designed for efficiency and market penetration. Direct sales from manufacturing sites handle bulk chemicals, often under long-term contracts, as seen in the Olefins segment's significant 2023 revenue. Strategic alliances, like those within Westlake Chemical Partners LP, ensure product integration and immediate sales through offtake agreements, contributing substantially to overall financial performance.

| Channel Type | Key Customer Segments | Primary Product Focus | 2023 Revenue Contribution (Illustrative) | 2024 Strategy Focus |

|---|---|---|---|---|

| Direct Sales | Large Industrial Clients, Chemical Manufacturers | Bulk Chemicals (Olefins), PVC Resin | Olefins: ~$6.2 Billion (via alliances) | Strengthening B2B relationships, optimizing logistics |

| Distributors/Wholesalers | Building Product Retailers, Smaller Businesses | PVC Compounds, Building Products | Vinyl Segment: Significant portion of overall revenue | Expanding network reach, ensuring local stock availability |

| Digital Platforms (Websites) | All Stakeholders (Customers, Investors) | Product Information, Technical Data, Company News | N/A (Lead Generation, Information Hub) | Enhancing technical support and online resources |

| Strategic Alliances/JVs | Offtake Partners, Allied Entities | Integrated Chemicals, Specialty Materials | Olefins: ~$6.2 Billion (benefit from alliances) | Product diversification, market access expansion |

Customer Segments

Construction and infrastructure companies form a vital customer segment for Westlake Chemical, encompassing those engaged in building homes, commercial spaces, and large-scale public works. Westlake's Housing and Infrastructure Products segment directly addresses these needs, supplying essential materials such as siding, roofing, pipes, and fittings.

This segment is particularly attractive due to sustained growth drivers in housing demand and infrastructure investment. For instance, in 2024, the U.S. housing market continued to see activity, with new housing starts projected to remain robust, supporting demand for Westlake's building products.

Packaging manufacturers are a crucial customer base for Westlake Chemical. These companies rely on Westlake's high-quality polymers, such as polyethylene and vinyls, to create a wide array of packaging solutions. This includes everything from the flexible films used for food packaging to the robust industrial containers needed for shipping and storage.

The demand for these materials is substantial, driven by global consumer needs for safe and convenient packaging. In 2024, the global packaging market was projected to reach over $1 trillion, with plastics forming a significant portion of this value, highlighting the importance of Westlake's polymer offerings to this expansive industry.

Healthcare and medical device manufacturers represent a vital customer segment for Westlake Chemical. These companies rely on Westlake's high-performance polymers for a wide array of critical applications, including the production of medical devices, sterile packaging for pharmaceuticals, and components for diagnostic equipment. The stringent regulatory environment and the need for absolute reliability in this sector mean that the quality and consistency of Westlake's materials are paramount.

The global medical device market was valued at approximately $520 billion in 2023 and is projected to grow significantly, driven by an aging population and advancements in medical technology. This growth directly translates to increased demand for specialized polymers, such as those offered by Westlake, which must meet rigorous standards for biocompatibility, durability, and chemical resistance. Westlake's commitment to innovation ensures they can supply materials that enable the development of safer and more effective healthcare solutions.

Automotive Industry

Automotive manufacturers and their extensive supplier networks are key customers for Westlake Chemical. They utilize Westlake's diverse portfolio of chemicals and polymers to create a wide array of vehicle components. These include everything from interior trim and seating materials to exterior coatings and specialized under-the-hood parts.

Westlake's commitment to innovation is particularly evident in its offerings for the rapidly evolving automotive sector. The company's advanced specialty resins and high-performance composites are increasingly being adopted for electric vehicles (EVs). These materials are crucial for lightweighting, battery components, and durable interior and exterior applications, reflecting the industry’s shift towards sustainability and advanced technology.

- Automotive Sector Demand: Westlake's products are integral to vehicle manufacturing, supplying essential materials for both traditional and new energy vehicles.

- Specialty Resins for EVs: The company provides advanced resins and composites specifically designed to meet the performance and lightweighting requirements of electric vehicles.

- Supplier Integration: Westlake works closely with automotive suppliers, ensuring their chemical inputs meet stringent industry standards and performance specifications.

Consumer Goods Manufacturers

Consumer Goods Manufacturers represent a vast and crucial customer segment for Westlake Chemical. This category includes companies that produce everything from the cleaning supplies in our homes to the latest gadgets and the clothes we wear. Westlake's essential chemicals and polymers are the building blocks for many of these products, making them an integral part of the consumer goods supply chain.

For instance, Westlake's polyethylene, a key polymer, is widely used in packaging for food, beverages, and household products, ensuring freshness and durability. In 2024, the global consumer packaged goods market was valued at over $10 trillion, underscoring the immense scale of this industry and Westlake's potential reach.

- Foundation of Everyday Products: Westlake's basic chemicals and polymers are fundamental inputs for a wide range of consumer goods, from plastics used in appliance casings to ingredients in personal care items.

- Packaging Solutions: A significant portion of Westlake's output, particularly polyethylene and PVC, is utilized in the packaging industry, critical for preserving and transporting consumer products.

- Market Reach: The sheer diversity of consumer goods means Westlake serves a broad spectrum of manufacturers, from large multinational corporations to smaller specialized producers.

- Economic Impact: In 2023, the global plastics market, a direct beneficiary of Westlake's products, was valued at approximately $600 billion, with significant growth driven by consumer demand.

Westlake Chemical’s customer segments are diverse, reflecting the fundamental nature of its chemical and polymer products. These segments span industries critical to daily life and economic activity, from construction and packaging to healthcare and consumer goods.

The company’s offerings are essential building blocks for manufacturers across these sectors. For example, Westlake’s vinyls and polyethylene are vital for creating packaging, pipes, and medical devices, demonstrating their broad applicability and importance in the global supply chain.

The demand within these segments is driven by consistent global needs and industry-specific growth trends. In 2024, the construction sector continued its recovery, while the packaging market’s value exceeded $1 trillion, underscoring the sustained relevance of Westlake’s product portfolio.

| Customer Segment | Key Products Supplied | Market Relevance/Data Point |

|---|---|---|

| Construction & Infrastructure | Siding, roofing, pipes, fittings | U.S. housing starts projected robust in 2024, supporting demand. |

| Packaging Manufacturers | Polyethylene, vinyls | Global packaging market projected over $1 trillion in 2024. |

| Healthcare & Medical Devices | High-performance polymers | Global medical device market valued at ~$520 billion in 2023. |

| Automotive | Specialty resins, composites | Increasing adoption for electric vehicles (EVs) due to lightweighting needs. |

| Consumer Goods | Polyethylene, PVC | Global consumer packaged goods market valued at over $10 trillion in 2024. |

Cost Structure

Raw materials, such as ethane, propane, and chlorine, along with energy like natural gas and electricity, represent the most substantial elements of Westlake Chemical's cost structure. These inputs are fundamental to their chemical manufacturing processes.

The company's profitability is directly influenced by the volatility of these commodity prices. For instance, Westlake reported higher feedstock and energy expenses in the first quarter of 2025, underscoring this sensitivity.

Westlake Chemical's manufacturing and operating expenses are substantial, reflecting the costs of running its global production network. These include labor, upkeep for facilities, energy consumption, and the depreciation of machinery and buildings. For instance, in 2023, Westlake reported cost of goods sold of $9.1 billion, a significant portion of which relates to these operational outlays.

The company places a strong emphasis on cost control and operational efficiency. A key strategy is vertical integration, which helps Westlake manage its supply chain and secure raw materials at competitive prices, reinforcing its global low-cost manufacturing advantage. This integration is crucial for maintaining profitability even during market fluctuations.

Westlake Chemical's logistics and distribution costs are a significant expense, driven by the need to move raw materials to its numerous manufacturing facilities and then transport finished products globally to a diverse customer base. These costs encompass freight charges for various modes of transportation, warehousing expenses for storing inventory, and the operational overhead associated with managing these complex supply chains.

In 2024, Westlake Chemical's commitment to an efficient global supply chain means substantial investment in these areas. For instance, the company's extensive network requires careful inventory management to balance availability with carrying costs, directly impacting their overall cost structure.

Research and Development (R&D) and Innovation Costs

Westlake Chemical's cost structure heavily features investments in Research and Development (R&D) and Innovation Costs. These expenditures are crucial for developing new products, improving existing ones, and exploring sustainable technologies, which directly fuels future growth and market competitiveness.

These R&D investments encompass a wide range of activities, including the salaries of scientists and engineers, the acquisition and maintenance of advanced laboratory equipment, and the funding of pilot programs to test new processes and materials. For instance, in 2024, Westlake continued its focus on innovation, allocating significant resources to projects aimed at enhancing product performance and reducing environmental impact.

- Personnel Costs: Salaries and benefits for R&D staff, including chemists, engineers, and technicians.

- Equipment and Facilities: Costs associated with laboratory equipment, testing apparatus, and pilot plant operations.

- New Product Development: Expenses related to the research, design, and initial testing of novel chemical products and materials.

- Sustainable Technologies: Investment in developing and implementing environmentally friendly manufacturing processes and products.

Selling, General, and Administrative (SG&A) Expenses

Selling, General, and Administrative (SG&A) expenses at Westlake Chemical encompass the necessary overhead to run its extensive operations. These include costs associated with sales and marketing efforts to reach customers, the salaries of corporate leadership and administrative staff, and the essential IT infrastructure supporting its global network. Westlake actively seeks to streamline these expenditures to boost efficiency without compromising the quality of its business functions or its capacity to manage its worldwide reach.

For instance, in 2024, Westlake Chemical reported significant investments in its SG&A structure to support its expanding product lines and market penetration. These costs are crucial for maintaining brand presence, managing complex supply chains, and ensuring regulatory compliance across its diverse geographic locations. The company's strategy involves leveraging technology and process improvements to manage these overheads effectively.

- Sales and Marketing: Costs incurred to promote and sell Westlake's chemical products globally.

- General and Administrative: Includes executive salaries, legal, finance, and human resources functions.

- IT Infrastructure: Investments in technology systems and support for its worldwide operations.

- Operational Efficiency: Focus on optimizing SG&A to maintain profitability and competitive pricing.

Westlake Chemical's cost structure is heavily weighted towards raw materials and energy, with significant operational expenses tied to its global manufacturing footprint. The company's profitability is sensitive to commodity price fluctuations, as seen in increased feedstock costs in early 2025. Investments in R&D and SG&A are critical for innovation and maintaining market presence.

Logistics and distribution costs are also substantial, reflecting the global movement of materials and products. Westlake's focus on vertical integration and operational efficiency aims to mitigate these costs and maintain a competitive edge.

| Cost Category | 2023 (USD Billions) | 2024 (Estimated/Projected) |

|---|---|---|

| Cost of Goods Sold | 9.1 | [Data to be updated closer to July 2025] |

| Raw Materials & Energy | [Significant portion of COGS] | [Subject to market volatility] |

| Manufacturing & Operating Expenses | [Includes labor, maintenance, depreciation] | [Ongoing operational outlays] |

| Logistics & Distribution | [Costs for global supply chain management] | [Investments in network efficiency] |

| R&D and Innovation | [Expenditures for new products/processes] | [Continued focus on sustainable technologies] |

| SG&A Expenses | [Overhead for sales, admin, IT] | [Investments supporting market expansion] |

Revenue Streams

Westlake Chemical's revenue primarily flows from selling fundamental chemicals such as ethylene, chlorine, and caustic soda, alongside polymers like polyethylene, PVC resin, and epoxy resins. These materials are the building blocks for countless industrial products.

The sales volume and pricing for these essential materials are directly tied to the ebb and flow of global demand and the volatile nature of commodity markets. For instance, in 2024, Westlake reported significant contributions from its Performance and Essential Materials segment, reflecting strong industrial activity.

Westlake Chemical generates substantial revenue from selling building products like siding, roofing, pipe, windows, and outdoor living items. This segment is a key driver of their earnings, benefiting directly from the health of both residential and commercial construction markets.

Westlake Chemical may also earn revenue by licensing its proprietary chemical technologies or offering specialized technical consulting services to other companies. This allows them to monetize their intellectual property and deep industry knowledge, particularly in areas where they hold a competitive advantage.

By-product Sales

Westlake Chemical generates revenue by selling by-products created during its primary chemical manufacturing. These by-products, which might otherwise be waste, are valuable commodities that contribute to a more efficient and profitable production cycle.

For instance, in 2023, Westlake Chemical reported total revenues of $11.0 billion. While specific figures for by-product sales are not broken out separately, this segment plays a role in optimizing overall financial performance by monetizing materials that arise from core operations.

- By-product Monetization: Westlake leverages secondary materials from its manufacturing processes as revenue sources.

- Value Optimization: This strategy enhances the economic return from its chemical production by finding markets for all outputs.

- Revenue Diversification: By-product sales offer an additional, albeit often smaller, income stream alongside its main product lines.

Strategic Partnership Distributions/Equity Income

Westlake Corporation’s revenue streams are diversified, including significant income from strategic partnerships and equity stakes. A prime example is its interest in Westlake Chemical Partners LP, a publicly traded master limited partnership. This structure allows Westlake to generate distributions and equity income, bolstering its overall financial performance and stability.

These partnerships are crucial for Westlake’s business model, providing a steady flow of income and often facilitating access to specific markets or technologies. The distributions received from these ventures are a key component of Westlake's earnings, contributing to its financial resilience.

- Strategic Partnership Income: Distributions and equity income from ventures like Westlake Chemical Partners LP.

- Financial Stability: These partnerships enhance the company's overall financial health and predictability of earnings.

- 2024 Performance Indicator: While specific 2024 figures for partnership distributions are subject to ongoing reporting, Westlake Chemical Partners LP’s performance in prior periods, such as its reported distributable cash flow, offers insight into the potential revenue contribution. For instance, in 2023, Westlake Chemical Partners LP reported significant cash flows that supported its distributions to unitholders, a trend expected to continue influencing Westlake Corporation's equity income.

Westlake’s revenue streams are primarily driven by the sale of essential chemicals and polymers, alongside a growing segment of building products. The company also benefits from strategic partnerships and the monetization of by-products from its manufacturing processes.

In 2023, Westlake reported total revenues of $11.0 billion. The company’s diverse product portfolio, ranging from ethylene and PVC to vinyl siding and roofing, positions it to capture value across various industrial and consumer markets.

The performance of its segments, such as Essential Materials and Housing & Infrastructure Products, directly impacts its revenue. For example, in the first quarter of 2024, Westlake noted robust demand in its building products segment, contributing positively to its financial results.

| Revenue Source | Key Products/Activities | 2023 Revenue Contribution (Illustrative) |

|---|---|---|

| Chemicals & Polymers | Ethylene, Chlorine, Caustic Soda, Polyethylene, PVC | Significant portion of total revenue |

| Building Products | Siding, Roofing, Pipe, Windows | Substantial and growing contributor |

| Partnerships/Investments | Distributions from Westlake Chemical Partners LP | Steady income stream |

| By-product Sales | Monetization of manufacturing by-products | Optimizes overall profitability |

Business Model Canvas Data Sources

The Westlake Chemical Business Model Canvas is informed by a combination of financial disclosures, market intelligence reports, and internal operational data. This ensures a robust understanding of customer segments, value propositions, and cost structures.