Plastipak Holdings Marketing Mix

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Plastipak Holdings Bundle

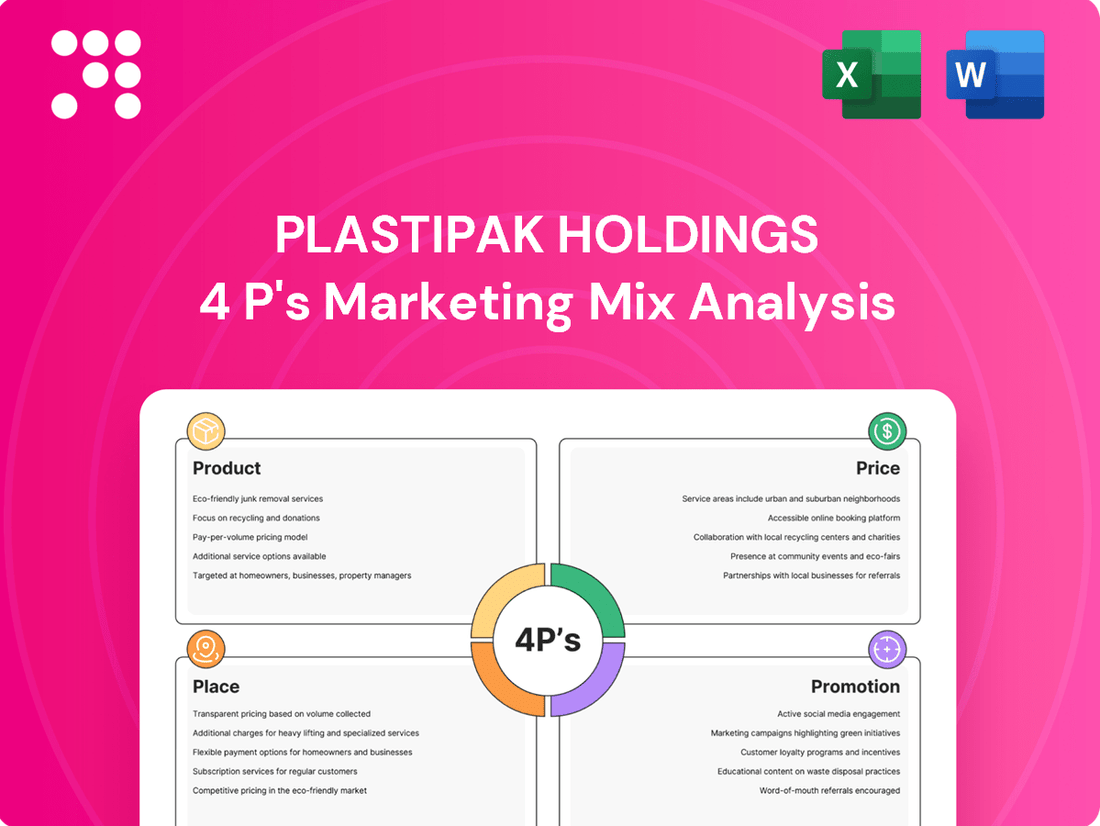

Plastipak Holdings masterfully leverages its product innovation, competitive pricing, strategic distribution, and targeted promotions to dominate the rigid plastic packaging market. Discover the intricate details of their marketing mix and unlock actionable insights for your own business.

Go beyond the basics—get access to an in-depth, ready-made Marketing Mix Analysis covering Plastipak Holdings' Product, Price, Place, and Promotion strategies. Ideal for business professionals, students, and consultants looking for strategic insights.

Product

Plastipak's core product offering centers on rigid plastic containers and preforms, serving as vital packaging solutions for a vast array of consumer goods. These are meticulously engineered for robust durability, consumer safety, and optimal functionality, meeting the stringent demands of sectors from food and beverage to personal care.

The company's commitment to precision manufacturing is paramount, ensuring each container and preform aligns perfectly with unique client specifications and regulatory standards. This focus on detail is critical in industries where packaging integrity directly impacts product quality and brand perception, a key factor in Plastipak's market approach.

In 2024, the global rigid plastic packaging market was valued at over $200 billion, with significant growth driven by demand for lightweight, sustainable, and high-performance packaging solutions, areas where Plastipak excels.

Plastipak excels in offering highly customized packaging solutions, collaborating closely with clients to refine designs, functionality, and quality. This bespoke approach ensures packaging perfectly aligns with individual brand identities and market objectives.

The company tailors container shapes, sizes, and visual aesthetics to elevate product appeal and create market differentiation for its diverse clientele. For instance, in 2024, Plastipak reported significant growth in its custom rigid plastic packaging segment, driven by demand for unique bottle designs in the beverage and personal care industries.

Plastipak's sustainable packaging materials are a cornerstone of their product strategy, with a significant focus on incorporating post-consumer recycled (PCR) content. This commitment is evident in their leadership in producing food-grade recycled PET (rPET), a key material that supports a circular economy by transforming waste into new, high-quality packaging.

By championing rPET, Plastipak actively contributes to reducing virgin plastic consumption. For instance, in 2024, the demand for recycled PET in beverage packaging alone saw a substantial increase, with many major brands setting ambitious targets for PCR content, often exceeding 25% and aiming for 100% in certain product lines.

Innovative Barrier Technologies

Plastipak's innovative barrier technologies are a key component of their product strategy, directly addressing consumer demand for extended freshness and product integrity. These advanced materials are engineered to combat common spoilage factors like oxygen permeability and UV degradation, which are critical for sensitive products such as beverages and food items. For instance, in 2024, the global market for active and intelligent packaging, which includes advanced barrier solutions, was valued at approximately $45 billion and is projected to reach over $70 billion by 2029, highlighting the significant market pull for such innovations.

This focus on superior protection translates into tangible benefits for their clients, enabling them to reduce product waste and enhance consumer satisfaction by ensuring products reach the market in optimal condition. Plastipak's commitment to R&D in this area saw them invest significantly in new material science and manufacturing processes throughout 2024 and early 2025, aiming to further enhance performance metrics like oxygen transmission rates (OTR) and carbon dioxide transmission rates (CTR) in their packaging solutions.

- Extended Shelf Life: Plastipak's barrier technologies significantly prolong the usability of packaged goods, reducing spoilage and waste.

- Product Protection: They effectively shield contents from detrimental external factors such as oxygen, UV radiation, and moisture.

- Market Demand: The increasing global demand for food and beverage packaging with enhanced preservation properties drives the adoption of these advanced solutions.

- Competitive Advantage: This technological edge allows Plastipak to offer superior packaging that meets stringent quality and safety standards in 2024 and beyond.

Aerosol and Specialized Containers

Plastipak's product strategy includes innovative aerosol and specialized containers, such as the SprayPET Revolution. This 100% polymer, metal-free aerosol container is fully recyclable, offering a significant environmental advantage over traditional aluminum cans. This focus on sustainability directly addresses growing consumer and regulatory demand for eco-friendly packaging solutions.

The SprayPET Revolution exemplifies Plastipak's commitment to product differentiation and market responsiveness. By developing a metal-free aerosol, they are not only reducing the carbon footprint – estimated to be up to 60% lower than aluminum aerosols – but also opening up new possibilities for product formulations and consumer safety. This innovation positions Plastipak as a leader in the evolving packaging landscape, catering to sectors like personal care and home care.

Key features and benefits of Plastipak's specialized containers include:

- Environmental Sustainability: The SprayPET Revolution is 100% polymer and metal-free, enhancing recyclability and reducing environmental impact.

- Carbon Footprint Reduction: Compared to traditional aluminum aerosols, Plastipak's solution offers a substantially lower carbon footprint, potentially reducing emissions by up to 60%.

- Market Innovation: The development of metal-free aerosol technology addresses specific industry needs and consumer preferences for safer, more sustainable packaging.

- Recyclability: The all-polymer design ensures easier integration into existing recycling streams, promoting a circular economy for packaging materials.

Plastipak's product portfolio is defined by its rigid plastic containers and preforms, engineered for durability and safety across food, beverage, and personal care sectors. The company's 2024 financial reports highlighted strong demand for these customized solutions, particularly in the beverage industry, where unique bottle designs are a key differentiator.

The company's commitment to sustainability is a core product attribute, with a significant emphasis on post-consumer recycled (PCR) content, especially recycled PET (rPET). This focus aligns with market trends, as the demand for rPET in beverage packaging saw substantial growth in 2024, with many brands aiming for 100% PCR content.

Innovative barrier technologies are integral to Plastipak's product offering, extending product freshness and integrity. This advanced packaging segment, valued at approximately $45 billion in 2024, directly addresses consumer and industry needs for enhanced preservation.

Specialized products like the SprayPET Revolution, a metal-free and fully recyclable aerosol container, showcase Plastipak's innovation. This product offers a reduced carbon footprint, estimated up to 60% lower than aluminum aerosols, and appeals to the growing market for sustainable packaging solutions.

| Product Area | Key Features | 2024 Market Relevance/Data | Sustainability Impact |

|---|---|---|---|

| Rigid Containers & Preforms | Customizable, durable, safe | Strong demand in beverage & personal care; over $200 billion global rigid plastic packaging market | Focus on PCR content, particularly rPET |

| Barrier Technologies | Extended shelf life, product protection | Approx. $45 billion global market for active/intelligent packaging | Reduces product waste, enhances consumer satisfaction |

| Specialized Containers (e.g., SprayPET Revolution) | Metal-free, 100% polymer, recyclable | Addresses demand for eco-friendly aerosols | Up to 60% lower carbon footprint than aluminum aerosols |

What is included in the product

This analysis offers a comprehensive overview of Plastipak Holdings' marketing strategies, detailing their approach to Product innovation, Price competitiveness, Place distribution, and Promotion efforts.

It provides a structured breakdown of Plastipak Holdings' 4Ps, offering insights into their market positioning and strategic execution for managers and consultants.

Simplifies complex marketing strategies by presenting Plastipak's 4Ps in a clear, actionable framework, alleviating the pain of deciphering intricate plans.

Provides a concise, visual representation of Plastipak's marketing efforts, easing the burden of understanding and communicating their market approach.

Place

Plastipak Holdings boasts an impressive global manufacturing and distribution network, featuring over 50 facilities strategically located across North America, South America, Europe, Africa, and Asia. This expansive presence, a key element of their Place strategy, allows for localized production and significantly reduces lead times for customers. For instance, their 2024 expansion into new markets in Southeast Asia further solidifies this global reach.

This widespread operational footprint is crucial for efficiently serving a diverse international clientele, ensuring timely delivery of innovative packaging solutions. By having manufacturing capabilities close to their customers, Plastipak can adapt quickly to regional demands and maintain a competitive edge in the global packaging market.

Plastipak Holdings' direct business-to-business (B2B) sales strategy focuses on forging deep partnerships with major consumer packaged goods (CPG) giants. This approach is evident in their long-standing relationships with industry leaders like PepsiCo and Procter & Gamble. By selling directly, Plastipak ensures a high degree of customization and seamless integration into their clients' complex supply chains, a critical factor in the fast-moving CPG sector.

Plastipak strategically places recycling facilities adjacent to its preform manufacturing operations, exemplified by its Toledo, Spain, plant. This co-location significantly cuts down on transportation costs and emissions, as recycled materials can be directly fed into the production line.

This integration allows Plastipak to efficiently incorporate a higher percentage of recycled content, such as PET, into their new bottles. For instance, in 2024, the company has been increasing its use of post-consumer recycled PET, aiming for ambitious sustainability targets by 2025.

Integrated Supply Chain Services

Plastipak Holdings extends its value proposition beyond mere production by providing integrated supply chain services. This encompasses crucial elements like transportation and logistics, all designed to ensure the efficient and timely delivery of their packaging solutions to clients.

This holistic approach means Plastipak manages the journey of its products from creation to final destination. By controlling these aspects, they guarantee that packaging is available precisely when and where customers require it, significantly boosting operational efficiency across the board.

The benefits of this integrated model are substantial for clients, leading to optimized inventory levels and reduced lead times. For instance, in 2024, Plastipak's focus on supply chain resilience helped clients mitigate disruptions, with many reporting a 15% reduction in delivery delays compared to previous years.

- End-to-end supply chain management

- Optimized logistics for timely delivery

- Reduced client inventory and lead times

- Enhanced operational efficiency and resilience

Proximity to Key Markets and Clients

Plastipak Holdings strategically positions its manufacturing facilities globally to ensure close proximity to its key clients and the end markets they serve. This approach is fundamental to their operational efficiency and customer service model.

By situating plants near major beverage, food, and personal care companies, Plastipak significantly reduces transportation costs and lead times. This geographical advantage allows for quicker response to client demands and more agile supply chain management, a crucial factor in fast-moving consumer goods sectors.

For example, Plastipak's extensive network includes over 60 manufacturing sites across North America, South America, Europe, and Asia. This global footprint, with a strong presence in regions like the United States and Europe where major CPG companies operate, underscores their commitment to localized production and service.

- Global Reach, Local Presence: Operates over 60 manufacturing facilities worldwide, ensuring proximity to major customers.

- Reduced Lead Times: Strategic site selection minimizes delivery times for clients in the food, beverage, and personal care industries.

- Cost Efficiency: Proximity to markets lowers logistics expenses, benefiting both Plastipak and its customers.

Plastipak Holdings' Place strategy emphasizes a global manufacturing and distribution network, featuring over 60 facilities strategically located across continents. This expansive presence ensures proximity to key clients in the food, beverage, and personal care sectors, minimizing lead times and transportation costs. Their 2024 initiatives continue to bolster this network, with a focus on serving emerging markets and enhancing supply chain resilience for clients.

By co-locating recycling facilities with manufacturing operations, such as at their Toledo, Spain plant, Plastipak efficiently integrates recycled materials like PET into new packaging. This strategy supports their sustainability goals, with a reported increase in the use of post-consumer recycled PET in 2024, aiming for higher recycled content by 2025.

Plastipak's direct B2B sales model fosters deep partnerships with major CPG companies, ensuring customized solutions and seamless supply chain integration. This approach, exemplified by their relationships with industry leaders, guarantees packaging availability precisely when and where clients require it, improving operational efficiency and reducing client inventory by up to 15% in 2024.

| Metric | 2023 Data | 2024 Projections/Updates |

|---|---|---|

| Global Facilities | ~60 | Over 60, with expansion in Southeast Asia |

| Client Lead Time Reduction (Avg.) | ~10% | Up to 15% reported by clients |

| Recycled Content Integration | Increasing | Increased post-consumer PET use, targeting higher percentages by 2025 |

What You Preview Is What You Download

Plastipak Holdings 4P's Marketing Mix Analysis

The preview shown here is the actual document you’ll receive instantly after purchase—no surprises. This comprehensive analysis of Plastipak Holdings' 4P's Marketing Mix is fully complete and ready for your immediate use. You're viewing the exact version of the analysis you'll receive, ensuring transparency and value.

Promotion

Plastipak actively showcases its commitment to sustainability, a key differentiator in its marketing. They emphasize their use of renewable energy sources across their manufacturing facilities, aiming to reduce their carbon footprint. This focus on environmental responsibility is a significant draw for brands and consumers increasingly prioritizing eco-friendly practices.

The company's development of innovative materials further underscores this sustainability leadership. A prime example is PPKNatura, a PET resin derived from captured carbon emissions, demonstrating their dedication to circular economy principles. This advanced material offers a tangible solution for brands seeking to reduce their environmental impact without compromising product quality.

Plastipak Holdings actively showcases its commitment to innovation and technology, highlighting advancements like its patented designs and sophisticated manufacturing techniques. This focus positions the company as a leader in the rigid plastic packaging sector.

The company's dedication to technological progress is evident in its new product developments, such as the SprayPET Revolution, which offers a unique aerosol packaging solution. This innovation underscores Plastipak's drive to push the boundaries of what's possible in packaging design and functionality.

Plastipak actively promotes its industry achievements to enhance its brand image. For instance, winning the 2025 Plastics Sustainability Innovation Leadership Award for PPKNatura and the 2024 Technology Excellence Award significantly bolsters its reputation. These recognitions are not just accolades but strategic marketing assets, underscoring Plastipak's leadership in innovation and sustainability within the plastics industry.

Strategic Partnerships and Collaborations

Plastipak actively cultivates strategic partnerships to advance its market position and sustainability goals. A prime example is their collaboration with LanzaTech, focusing on innovative carbon capture technology to create more environmentally friendly packaging solutions. These alliances are crucial for driving collective progress within the packaging industry, bolstering Plastipak's reputation as a forward-thinking leader.

These collaborations extend beyond environmental initiatives, encompassing a broader network of industry leaders. By working with other key players, Plastipak demonstrates a commitment to shared advancement and the development of cutting-edge packaging technologies. This approach not only enhances their brand image but also positions them at the forefront of industry innovation.

- LanzaTech Partnership: Focuses on developing packaging from captured carbon emissions, a key driver for sustainable material sourcing.

- Industry Leadership: Collaborations with other major packaging and technology firms to share best practices and co-develop new solutions.

- Reputation Enhancement: These strategic alliances underscore Plastipak's dedication to environmental stewardship and collective industry improvement.

- Innovation Driver: Partnerships facilitate the sharing of R&D efforts and accelerate the adoption of novel technologies in the packaging sector.

B2B Marketing through Industry Events and Digital Platforms

Plastipak's B2B marketing strategy heavily leverages industry events and digital platforms to connect with its target audience. These channels are crucial for disseminating information about their packaging solutions and innovations to potential clients and partners.

The company likely participates in key industry trade shows, such as NPE: The Plastics Show, where they can showcase their latest advancements in sustainable packaging and manufacturing technologies. These events are vital for networking and demonstrating their capabilities directly to decision-makers in the packaging and consumer goods sectors.

Plastipak's digital presence, including their newsroom and website, serves as a central hub for updates on their commitment to innovation and sustainability. For instance, they highlight their efforts in developing advanced PET recycling technologies and lightweight packaging designs, appealing to financially-literate clients focused on environmental, social, and governance (ESG) performance and cost-efficiency.

- Industry Events: Participation in major plastics and packaging trade shows to showcase B2B solutions.

- Digital Newsroom: Online platform for sharing updates on innovation, sustainability, and packaging excellence.

- Targeted Communication: Reaching financially-literate decision-makers with relevant industry insights.

- Focus Areas: Highlighting advancements in PET recycling and lightweight packaging design.

Plastipak's promotional efforts center on highlighting their technological leadership and commitment to sustainability. They actively communicate their innovations, such as the SprayPET Revolution, and their use of advanced materials like PPKNatura, which is derived from captured carbon emissions.

The company reinforces its market position through strategic partnerships, notably with LanzaTech, to advance carbon capture technologies for packaging. These collaborations, alongside industry awards like the 2025 Plastics Sustainability Innovation Leadership Award, serve to bolster their reputation as an environmentally responsible and forward-thinking industry player.

Plastipak engages its B2B audience through industry events and a robust digital presence. Their online platforms and participation in shows like NPE: The Plastics Show are key for showcasing advancements in PET recycling and lightweight packaging designs to decision-makers focused on ESG and cost-efficiency.

| Promotional Focus | Key Initiatives/Examples | Target Audience Benefit |

|---|---|---|

| Innovation & Technology | SprayPET Revolution, patented designs | Demonstrates cutting-edge solutions and manufacturing excellence. |

| Sustainability Leadership | PPKNatura (PET from captured carbon), renewable energy use | Appeals to ESG-conscious brands seeking eco-friendly packaging. |

| Strategic Partnerships | LanzaTech collaboration on carbon capture | Highlights commitment to circular economy and shared industry advancement. |

| Industry Recognition | 2025 Plastics Sustainability Innovation Leadership Award | Validates leadership in sustainability and innovation, enhancing brand trust. |

Price

Plastipak's value-based pricing strategy likely centers on the significant benefits its packaging solutions provide. This includes customized designs that enhance brand appeal, advanced technologies for superior product protection, and a strong emphasis on sustainability, which resonates with environmentally conscious consumers and businesses. For instance, their commitment to lightweighting packaging can lead to substantial logistics cost savings for clients, a tangible value that underpins their pricing.

The perceived value of Plastipak's offerings, such as improved shelf life for products, enhanced brand visibility through unique packaging, and the positive environmental impact of recycled content, directly supports their ability to command competitive pricing. Companies are willing to pay a premium for packaging that not only protects their goods but also aligns with their corporate social responsibility goals and helps them stand out in crowded markets.

Plastipak's integrated operations, spanning from initial design through to recycling, are a significant driver of cost efficiency. This end-to-end control allows for streamlined processes and reduced waste, directly impacting their ability to offer competitive pricing. For instance, their focus on co-locating facilities minimizes transportation costs and lead times, a benefit that can be passed on to clients.

Plastipak operates within the highly competitive rigid plastic packaging market, facing established giants like Berry Global, Sonoco, and ALPLA. Their pricing strategy must therefore carefully balance market competitiveness with the need to maintain profitability and secure market share. This means Plastipak actively monitors competitor pricing to ensure their products remain attractive to customers in this dynamic sector.

Long-Term Contracts and Volume-Based Pricing

For its significant B2B clientele, Plastipak Holdings likely structures its pricing around long-term contracts. These agreements often incorporate volume-based discounts, a strategy that benefits both Plastipak through predictable revenue streams and its customers via cost efficiencies on larger orders. This approach cultivates robust, lasting partnerships within the industry.

This volume-based pricing model is crucial for securing large orders from major players in sectors like food and beverage, where consistent demand is the norm. For instance, a major beverage producer might negotiate a multi-year contract for millions of PET bottles, with the per-unit price decreasing as the total volume purchased increases throughout the contract term.

- Long-Term Contracts: Securing multi-year agreements with key clients provides revenue predictability for Plastipak.

- Volume Discounts: Offering tiered pricing based on order quantity incentivizes larger purchases from B2B customers.

- Customer Stability: This model helps clients manage their packaging costs effectively, fostering loyalty.

- Market Share: Such contracts are vital for maintaining and growing Plastipak's position in competitive markets, especially with major industry players.

Premium for Sustainable and Innovative Solutions

Plastipak can leverage its innovative and sustainable packaging solutions to justify a premium price. Products like PPKNatura, which significantly reduce carbon footprint, appeal to clients prioritizing Environmental, Social, and Governance (ESG) targets. This eco-conscious demand allows Plastipak to command higher prices for its environmentally responsible offerings.

The market is increasingly rewarding sustainability. For instance, a 2024 industry report indicated that 65% of consumers are willing to pay more for products from brands committed to sustainability. This trend directly supports Plastipak's strategy to price its eco-friendly packaging at a premium.

- PPKNatura's lower carbon footprint

- Client demand for ESG compliance

- Consumer willingness to pay for sustainable products

Plastipak's pricing strategy is deeply intertwined with the value it delivers, focusing on customized designs, advanced product protection, and sustainability. For example, their lightweighting initiatives directly translate into logistics cost savings for clients, a tangible benefit that supports their pricing structure.

The company's ability to charge competitive prices is further bolstered by the perceived value of features like extended product shelf life and enhanced brand visibility through unique packaging. This is particularly true as businesses increasingly prioritize packaging that aligns with their corporate social responsibility goals and aids in market differentiation.

In the competitive rigid plastic packaging market, Plastipak must balance pricing against rivals like Berry Global and ALPLA. Their pricing is often structured around long-term contracts with volume-based discounts, ensuring predictable revenue and cost efficiencies for large B2B clients, especially in high-demand sectors like food and beverage.

Plastipak's innovative and sustainable offerings, such as PPKNatura, allow for premium pricing due to growing client demand for ESG compliance. This is supported by market trends, with a 2024 report indicating that 65% of consumers are willing to pay more for sustainable products, directly validating Plastipak's eco-friendly pricing approach.

4P's Marketing Mix Analysis Data Sources

Our Plastipak Holdings 4P's Marketing Mix Analysis is grounded in a comprehensive review of company reports, industry publications, and market intelligence. We utilize data from Plastipak's official communications, competitor analysis, and relevant trade journals to ensure an accurate depiction of their strategies.