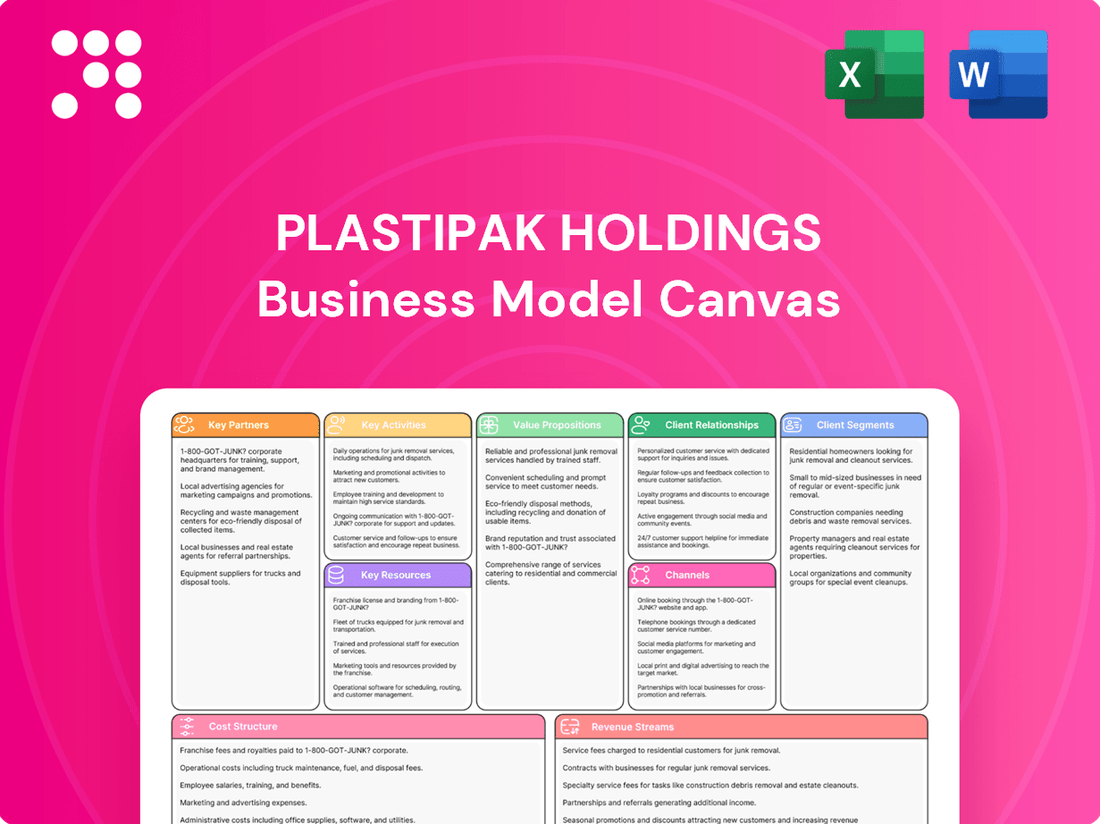

Plastipak Holdings Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

Plastipak Holdings Bundle

Discover the strategic core of Plastipak Holdings with our comprehensive Business Model Canvas. This detailed breakdown illuminates their customer relationships, revenue streams, and key resources, offering a clear view of their operational success. Understand how Plastipak Holdings innovates and maintains its competitive edge.

Ready to unlock the full picture? Download the complete Plastipak Holdings Business Model Canvas to gain actionable insights into their value propositions, cost structure, and key activities. It's the perfect tool for anyone looking to learn from a leader in the packaging industry.

Partnerships

Plastipak Holdings cultivates vital relationships with suppliers of virgin PET resin, HDPE, and other plastic raw materials. These partnerships are foundational, guaranteeing a steady flow of high-quality primary materials needed for their extensive manufacturing operations, including specialized resins like PPKNatura.

The company also prioritizes collaborations with suppliers offering recycled content and bio-based materials, aligning with their strong commitment to sustainability initiatives. For instance, the growing demand for sustainable packaging in 2024 means Plastipak actively seeks partners who can provide a reliable supply of post-consumer recycled (PCR) PET, with global markets for PCR PET resin showing significant growth.

Plastipak Holdings relies on key partnerships with technology and equipment providers to stay ahead. These collaborations are crucial for sourcing advanced machinery for processes like blow molding and injection molding, essential for their innovative packaging designs.

For example, partnerships with companies offering cutting-edge barrier technologies allow Plastipak to develop packaging that extends product shelf life and maintains product integrity. This access to state-of-the-art production capabilities directly impacts their ability to deliver high-performance solutions to their clients.

Plastipak's commitment to bottle-to-bottle recycling relies heavily on robust relationships with entities that manage plastic waste. These include local government waste management programs, large-scale waste hauling companies, and various private recycling organizations. These partnerships are crucial for securing a consistent supply of post-consumer plastic, the essential feedstock for Plastipak's advanced Clean Tech recycling facilities.

These collaborations are not just about material acquisition; they also play a vital role in scaling up recycling efforts. For instance, in 2024, many municipalities reported increased plastic collection rates due to enhanced public-private partnerships in recycling infrastructure. This expansion of collection networks directly supports Plastipak's operational capacity and its ability to process a greater volume of recyclable materials.

Consumer Goods Brand Owners

Plastipak's strategic alliances with major consumer goods giants like Kraft Heinz, Pepsi, and Procter & Gamble are foundational. These collaborations go beyond simple supply agreements, focusing on co-developing innovative packaging that aligns with client needs and increasingly stringent sustainability targets.

These partnerships are crucial for driving the adoption of advanced materials and designs. For instance, working with these brands facilitates the transition to solutions like 100% recycled PET (rPET) containers, a significant step in reducing environmental impact and meeting consumer demand for eco-friendly products.

- Strategic Alliances: Partnerships with Kraft Heinz, Pepsi, Dr Pepper Snapple Group, and Procter & Gamble are key.

- Co-Development: Jointly creating customized packaging solutions tailored to specific product requirements.

- Sustainability Focus: Emphasis on developing environmentally friendly packaging, such as 100% rPET containers.

- Market Impact: These collaborations enable Plastipak to influence packaging trends across major consumer product categories.

Research and Development Collaborators

Plastipak actively engages with research institutions and forward-thinking companies to pioneer sustainable packaging. A prime example is their collaboration with LanzaTech, a leader in carbon capture and transformation technology.

This partnership has been instrumental in developing innovative materials, such as PPKNatura. This unique PET resin is manufactured using captured carbon emissions, showcasing a tangible commitment to circular economy principles.

- LanzaTech Partnership: Focuses on developing PET resin from captured carbon emissions.

- PPKNatura Development: A direct outcome of R&D collaboration, utilizing waste carbon for material production.

- Innovation Driver: These alliances are crucial for Plastipak's advancement in eco-friendly packaging technologies and market leadership.

Plastipak's key partnerships with major consumer goods companies like Kraft Heinz and PepsiCo are critical for co-developing innovative and sustainable packaging solutions. These collaborations, often focused on increasing the use of recycled content, such as 100% rPET, directly influence market trends and consumer adoption of eco-friendly packaging. In 2024, the demand for sustainable packaging continued to surge, making these strategic alliances vital for Plastipak's growth and market leadership.

| Partner | Focus Area | 2024 Impact/Trend |

|---|---|---|

| Kraft Heinz | Sustainable packaging solutions, reduced plastic usage | Increased adoption of rPET in their product lines. |

| PepsiCo | Circular economy initiatives, lightweighting | Expansion of recycled content in beverage bottles. |

| Procter & Gamble | Innovative material science, product protection | Development of advanced barrier technologies for longer shelf life. |

| LanzaTech | Carbon capture and utilization for PET production | Advancement in bio-based and recycled PET materials like PPKNatura. |

What is included in the product

Plastipak Holdings' Business Model Canvas focuses on providing innovative rigid plastic packaging solutions, leveraging strong customer relationships and efficient manufacturing to serve diverse industries.

It details key partners in raw material supply and technology, supported by a robust cost structure and revenue streams from high-volume production and custom design services.

Plastipak Holdings' Business Model Canvas acts as a pain point reliever by providing a clear, one-page snapshot of their operations, enabling quick identification of inefficiencies and opportunities for optimization in their plastic packaging solutions.

This model effectively addresses the pain of complex strategic planning by condensing Plastipak's approach into a digestible format, facilitating rapid understanding and adaptation for stakeholders.

Activities

Plastipak's core activity revolves around the innovative design and engineering of rigid plastic packaging. This encompasses creating custom molds, ensuring package durability, and integrating advanced features like lightweighting and enhanced barrier technologies to protect products.

Their dedicated Creative Packaging Studios are central to this process, fostering direct collaboration with clients. This partnership approach allows for the swift development and market introduction of novel packaging solutions tailored to specific customer needs.

Plastipak's core activity revolves around the large-scale manufacturing of plastic containers and preforms. This global operation, spanning over 60 facilities, utilizes advanced techniques like blow molding and injection molding to produce high-quality, consistent products. In 2024, the company continued to focus on optimizing these processes to meet escalating global demand for its diverse product lines.

Plastipak's recycling operations are central to their business, transforming used plastic bottles into valuable food-grade recycled PET (rPET) and HDPE resins. This direct 'bottle-to-bottle' recycling process is a significant advantage, allowing them to create high-quality materials for new packaging.

These activities directly support a circular economy by significantly reducing the need for virgin plastic. For instance, in 2024, the demand for recycled content in plastic packaging continued to surge, with many major brands setting ambitious targets for incorporating rPET, a trend Plastipak is well-positioned to capitalize on.

Supply Chain Management and Logistics

Plastipak's key activities heavily involve managing a complex global supply chain. This encompasses everything from sourcing raw materials like PET resin to delivering finished plastic containers to customers across various industries. Optimizing logistics, including transportation and warehousing, is crucial for efficiency.

Effective inventory management is another core activity, ensuring that the right amount of materials and finished goods are available without excess costs. Timely delivery is paramount for customer satisfaction, particularly for high-volume clients in the beverage and consumer goods sectors.

- Raw Material Procurement: Securing consistent and cost-effective supplies of PET resin and other necessary inputs globally.

- Logistics and Transportation: Managing the movement of raw materials to plants and finished goods to customers efficiently, utilizing various modes of transport.

- Inventory Control: Maintaining optimal levels of raw materials, work-in-progress, and finished goods to meet demand while minimizing holding costs.

- Demand Forecasting: Accurately predicting customer demand to align production and supply chain operations.

Sustainability Initiatives and R&D for Circularity

Plastipak is actively driving sustainability by implementing initiatives like setting science-based targets for emissions reduction. They are also investing in renewable energy, such as solar and biogas, to power their operations.

A significant focus of their ongoing research and development is on circularity. This includes pioneering new materials and designs to minimize environmental impact.

- Developing Metal-Free Aerosol Containers: This innovation aims to simplify recycling processes and reduce reliance on mixed materials.

- Utilizing Carbon-Captured Resins: Plastipak is exploring and integrating resins derived from captured carbon, transforming a waste product into a valuable resource.

- Science-Based Targets: The company is committed to aligning its emissions reduction goals with scientific recommendations to combat climate change effectively.

- Renewable Energy Investments: Investments in solar and biogas power demonstrate a tangible commitment to reducing their carbon footprint through clean energy adoption.

Plastipak's key activities center on the innovative design and engineering of rigid plastic packaging, coupled with large-scale manufacturing of containers and preforms across its global facilities. Their operations are deeply integrated with robust recycling processes, transforming used plastic into high-quality recycled resins for new packaging, thereby championing a circular economy.

Managing a sophisticated global supply chain, from raw material procurement to efficient logistics and inventory control, is fundamental to their business model. This ensures consistent product delivery and customer satisfaction.

Furthermore, Plastipak actively pursues sustainability through science-based targets, investments in renewable energy, and the development of novel, eco-friendly packaging solutions, including metal-free aerosol containers and the use of carbon-captured resins.

| Key Activity | Description | 2024 Focus/Impact |

|---|---|---|

| Packaging Design & Engineering | Creating custom molds and advanced packaging features. | Swift development of novel solutions through client collaboration. |

| Large-Scale Manufacturing | Producing containers and preforms using blow and injection molding. | Optimizing processes to meet escalating global demand. |

| Recycling Operations | Transforming used plastic into food-grade rPET and HDPE resins. | Capitalizing on surging demand for recycled content in packaging. |

| Supply Chain Management | Sourcing raw materials, logistics, and inventory control. | Ensuring timely delivery and efficient operations for high-volume clients. |

| Sustainability Initiatives | Reducing emissions, investing in renewables, developing circular materials. | Pioneering new materials and designs for minimal environmental impact. |

Full Version Awaits

Business Model Canvas

The Plastipak Holdings Business Model Canvas you are previewing is the authentic document you will receive upon purchase. This is not a sample or mockup; it's a direct representation of the complete, ready-to-use file. Once your order is processed, you'll gain full access to this exact Business Model Canvas, allowing you to immediately leverage its insights for strategic planning.

Resources

Plastipak's global manufacturing and infrastructure is a cornerstone of its business, featuring over 60 strategically positioned facilities worldwide. This extensive network spans North America, South America, Europe, Africa, and Asia, ensuring close proximity to key markets and customers.

These facilities are equipped with specialized machinery and advanced technology crucial for both high-volume plastic container production and innovative recycling processes. This robust physical infrastructure is a significant competitive advantage, enabling efficient operations and scalability.

In 2024, Plastipak continued to invest in modernizing its infrastructure, focusing on automation and sustainability to enhance production capacity and reduce environmental impact. Their commitment to advanced manufacturing techniques underpins their ability to deliver quality products reliably.

Plastipak Holdings' proprietary technology is a cornerstone of its business model, evidenced by its extensive patent portfolio. As of early 2024, the company held over 420 US patents, a testament to its commitment to innovation in packaging. This intellectual property covers a wide range of advancements, from novel package designs to sophisticated manufacturing processes and cutting-edge recycling technologies.

These patents, including those for proprietary technologies like ThermoShape™ and SprayPET Revolution, create a substantial competitive moat for Plastipak. This protected innovation allows the company to develop and offer unique, high-performance, and increasingly sustainable packaging solutions that differentiate it in the market.

Plastipak Holdings relies heavily on its highly skilled workforce, encompassing engineers, designers, manufacturing specialists, and recycling experts. This human capital is the engine driving innovation in packaging solutions and ensuring operational efficiency across its global facilities.

The collective expertise of these professionals is paramount for Plastipak's success, particularly in navigating the complexities of advanced recycling technologies and fostering collaborative partnerships with customers to develop sustainable packaging solutions.

In 2024, Plastipak continued to invest in its workforce development programs, recognizing that experienced leadership and dedicated associates are indispensable assets. This focus on human resources directly supports the company's commitment to delivering high-quality, innovative, and environmentally responsible packaging products.

Recycling Infrastructure and Capabilities

Plastipak's recycling infrastructure, featuring dedicated centers like Clean Tech, is a cornerstone resource. These facilities possess significant capacity to transform post-consumer plastic into premium recycled resins, enabling closed-loop packaging solutions.

- Capacity: Plastipak's Clean Tech facilities process a substantial volume of post-consumer plastic, contributing to a circular economy.

- Integrated Solutions: This internal recycling capability allows Plastipak to offer unique closed-loop packaging systems to its clients.

- Market Demand: The infrastructure directly addresses the escalating market demand for products containing high percentages of recycled content.

- Quality Output: The advanced processing ensures the recycled resins meet stringent quality standards for new packaging applications.

Financial Capital and Investments

Plastipak Holdings requires substantial financial capital to fuel its extensive operations, including investments in cutting-edge technologies, facility expansions, and strategic acquisitions. This robust financial backing is crucial for maintaining its global market position, advancing sustainability initiatives, and supporting its massive production capabilities.

As a privately held entity, Plastipak's financial strength is anchored by the Young family's ownership. This structure allows for long-term strategic planning without the immediate pressures of public market demands.

- Capital Requirements: Significant investment is needed for R&D, new machinery, and capacity upgrades to stay competitive in the packaging industry.

- Financial Strength: The company's financial health enables it to undertake large projects and weather market fluctuations.

- Ownership Structure: Being privately held by the Young family provides stability and a clear vision for sustained growth and investment.

- Investment Focus: Capital is allocated towards innovation, operational efficiency, and environmental stewardship, ensuring long-term value creation.

Plastipak's key resources include its expansive global manufacturing footprint, boasting over 60 facilities, and a robust portfolio of over 420 US patents as of early 2024. The company also leverages its highly skilled workforce, crucial for innovation and operational excellence, and its dedicated recycling infrastructure, exemplified by Clean Tech facilities. Substantial financial capital, supported by the stable ownership of the Young family, underpins these operations and future investments.

| Resource Category | Key Components | 2024/Recent Data Points |

|---|---|---|

| Physical Infrastructure | Global Manufacturing Facilities | 60+ facilities worldwide |

| Intellectual Property | Proprietary Technologies & Patents | Over 420 US patents (early 2024) |

| Human Capital | Skilled Workforce (Engineers, Designers, Specialists) | Investment in workforce development programs |

| Recycling Infrastructure | Dedicated Recycling Centers (e.g., Clean Tech) | Significant capacity for post-consumer plastic processing |

| Financial Capital | Investment Funds & Ownership Structure | Privately held by the Young family; ongoing capital allocation for R&D and expansion |

Value Propositions

Plastipak excels in creating innovative and highly customized packaging. They engineer unique designs that not only protect products but also help brands stand out and appeal to consumers. This focus on tailored solutions is a core part of their value proposition.

A prime example of their innovation is the SprayPET Revolution, a technology that allows for aerosol dispensing directly from PET bottles. This kind of forward-thinking engineering demonstrates Plastipak's commitment to providing customers with distinctive and high-performing packaging options that can drive market success.

Plastipak's commitment to sustainability is a core value proposition, demonstrated through their comprehensive recycling services. In 2024, they continued to expand their capabilities, processing millions of pounds of post-consumer resin. This focus on circularity directly supports customers seeking to reduce their environmental footprint.

The company's dedication to using high percentages of recycled content in their products, such as their innovative PPKNatura material, further solidifies this value. This not only diverts waste from landfills but also appeals to a growing segment of eco-conscious consumers who prioritize sustainable purchasing decisions.

Plastipak Holdings offers rigid plastic packaging that stands out for its superior quality and performance. This means the packaging is built to last, protecting products effectively and contributing to a longer shelf life for various consumer goods. In 2024, the demand for such reliable packaging solutions remained high across sectors like food and beverage, personal care, and household products.

Customers can trust Plastipak's packaging due to their stringent testing protocols and commitment to industry-specific standards. This dedication ensures the safety and dependable functionality of every container. The global rigid plastic packaging market, valued at over $200 billion in recent years, continues to see growth driven by these quality-focused manufacturers.

Integrated Packaging Lifecycle Management

Plastipak's integrated packaging lifecycle management simplifies operations for clients by overseeing everything from initial design and manufacturing through to marketing and end-of-life recycling. This holistic approach ensures a seamless and efficient experience, fostering consistency across all stages of packaging development and deployment.

This comprehensive service model streamlines complex processes for customers, allowing them to focus on their core business while Plastipak manages the intricacies of packaging. In 2024, Plastipak continued to invest in advanced recycling technologies, aiming to increase the use of post-consumer recycled (PCR) content in its packaging solutions, aligning with growing market demand for sustainable options.

- Design and Development: Offering innovative and functional packaging designs tailored to specific product needs.

- Manufacturing Excellence: Utilizing state-of-the-art facilities to produce high-quality rigid plastic containers.

- Supply Chain Integration: Ensuring reliable delivery and efficient logistics from production to market.

- Sustainability and Recycling: Championing circular economy principles through advanced recycling and material innovation.

Global Reach and Reliable Supply

Plastipak's global presence, boasting over 60 manufacturing facilities across the globe, directly translates into a significant competitive advantage. This extensive network ensures a robust and reliable supply chain, a critical factor for multinational clients who depend on consistent product availability and timely delivery.

This widespread operational footprint provides Plastipak with unparalleled geographic flexibility. It allows the company to adapt quickly to regional market demands and disruptions, offering responsiveness that is essential in today's dynamic global economy. For instance, in 2024, Plastipak continued to leverage its international sites to mitigate supply chain risks identified earlier in the decade.

- Global Manufacturing Footprint: Over 60 facilities worldwide.

- Supply Chain Reliability: Ensures consistent product availability for multinational customers.

- Geographic Flexibility: Enables responsiveness to diverse and evolving market demands.

- Efficient Delivery: Facilitates streamlined logistics and reduced lead times.

Plastipak offers advanced rigid plastic packaging solutions, focusing on innovation and superior performance to protect products and enhance brand appeal. Their commitment to quality ensures reliable functionality, a crucial factor in sectors like food and beverage, where consistent packaging is paramount.

The company's integrated lifecycle management simplifies client operations from design to recycling, providing a seamless experience. In 2024, Plastipak's continued investment in advanced recycling technologies, including increasing post-consumer recycled content, underscored their dedication to sustainability.

Plastipak's value proposition is further strengthened by its extensive global manufacturing footprint, with over 60 facilities worldwide. This broad network ensures supply chain reliability and geographic flexibility, enabling responsiveness to diverse market demands and mitigating potential disruptions.

| Value Proposition | Description | Key Data/Fact |

|---|---|---|

| Innovative & Customized Packaging | Engineering unique designs that differentiate brands. | SprayPET Revolution technology. |

| Sustainability & Recycling | Promoting circularity through recycling services and high recycled content. | Processed millions of pounds of post-consumer resin in 2024. |

| Superior Quality & Performance | Producing durable, high-performing rigid plastic containers. | Global rigid plastic packaging market valued over $200 billion. |

| Integrated Lifecycle Management | Streamlining packaging operations from design to end-of-life. | Investment in advanced recycling technologies in 2024. |

Customer Relationships

Plastipak Holdings cultivates enduring customer loyalty via dedicated account management, ensuring each client receives personalized attention to their unique packaging requirements. This focused approach allows for proactive problem-solving and tailored solutions, fostering deep partnerships.

Their robust technical support teams are instrumental in this relationship building, offering expert guidance from initial concept through production and beyond. This commitment to ongoing assistance, particularly in navigating complex packaging challenges, solidifies Plastipak's role as a trusted advisor and partner, not just a supplier.

Plastipak Holdings actively engages customers in its Creative Packaging Studios, a key element of their customer relationships. This involves customers directly in the ideation, design, and prototyping of new packaging, fostering a deep sense of partnership.

This collaborative design process ensures that Plastipak's packaging solutions are not just functional but also perfectly tailored to meet specific customer brand identities and market demands. For instance, in 2024, a significant portion of new product development projects involved direct customer input from the initial concept stage.

Plastipak actively cultivates strategic partnerships with major clients, focusing on co-creating solutions to meet ambitious sustainability targets. These collaborations often center on increasing recycled content in packaging or designing materials for complete recyclability.

This joint approach not only deepens client loyalty but also underscores a mutual dedication to environmental responsibility, a crucial aspect in today's market. For instance, in 2023, Plastipak announced a significant expansion of its use of post-consumer recycled (PCR) PET, driven by these very partnerships with leading beverage brands aiming for higher PCR content goals.

Problem-Solving and Innovation Support

Plastipak actively engages with clients to tackle intricate packaging dilemmas, showcasing its commitment to innovation. By harnessing its robust research and development, the company delivers cutting-edge solutions that adapt to shifting market needs and stricter regulations. This collaborative problem-solving fosters deep customer loyalty.

For instance, in 2024, Plastipak's investment in advanced material science research led to the development of lighter-weight, yet equally durable, PET containers. This innovation directly addressed customer demands for reduced material usage and improved sustainability metrics, a key driver in the beverage packaging sector. Their R&D pipeline is consistently focused on anticipating future regulatory changes, such as those concerning recycled content mandates.

- Proactive Problem Solving: Plastipak doesn't just supply packaging; it partners with clients to overcome specific design and performance hurdles.

- Innovation Driven: Significant R&D investment in 2024 enabled the creation of next-generation packaging solutions addressing sustainability and performance.

- Customer Loyalty: This approach of providing tailored, innovative solutions directly translates into enhanced customer retention and satisfaction.

- Market Responsiveness: Plastipak's ability to anticipate and respond to evolving market trends and regulatory landscapes solidifies its role as a trusted partner.

Long-Term Contracts and Preferred Supplier Status

Plastipak often secures its customer relationships through long-term contracts, designating it as a preferred or even sole supplier for essential packaging. This deep integration into client supply chains underscores a significant level of trust and commitment.

These agreements provide Plastipak with predictable revenue streams and foster mutual growth by ensuring consistent demand for its specialized packaging solutions. For instance, in 2024, a significant portion of Plastipak's revenue was derived from these multi-year agreements, reflecting the stability they offer.

- Long-Term Contracts: Many customer relationships are solidified through multi-year agreements, ensuring consistent business volume.

- Preferred/Sole Supplier Status: Plastipak is frequently designated as a top-tier or exclusive provider for critical packaging needs, highlighting strong customer reliance.

- Supply Chain Integration: These relationships signify deep trust and embed Plastipak within the operational fabric of its clients' businesses.

- Mutual Growth: The long-term nature of these partnerships facilitates shared expansion and development, benefiting both Plastipak and its customers.

Plastipak Holdings fosters deep customer relationships through dedicated account management and robust technical support, positioning itself as a collaborative partner. By actively involving clients in the design process through its Creative Packaging Studios, Plastipak ensures tailored solutions that align with brand identity and market needs. This commitment to co-creation and problem-solving, exemplified by 2024 innovations in lighter-weight PET containers driven by customer demand for sustainability, solidifies customer loyalty and positions Plastipak as a responsive innovator.

Long-term contracts and preferred supplier status are key to securing these relationships, integrating Plastipak deeply into client supply chains and providing predictable revenue. This strategic approach, evident in 2024 revenue streams heavily reliant on multi-year agreements, fosters mutual growth and underscores a high level of trust and commitment between Plastipak and its clientele.

| Key Relationship Drivers | Description | Impact |

| Dedicated Account Management | Personalized attention to client packaging needs. | Fosters deep partnerships and proactive problem-solving. |

| Technical Support | Expert guidance from concept to production. | Establishes Plastipak as a trusted advisor. |

| Creative Packaging Studios | Direct customer involvement in design and prototyping. | Ensures tailored, brand-aligned solutions. |

| Long-Term Contracts | Multi-year agreements securing preferred/sole supplier status. | Provides predictable revenue and supply chain integration. |

Channels

Plastipak Holdings heavily relies on its direct sales force to connect with significant players in the consumer goods and industrial sectors. This direct approach facilitates clear communication, enabling the negotiation of tailored solutions that precisely meet client needs.

This direct engagement is crucial for fostering robust, personal relationships with the key decision-makers at these large organizations. For instance, in 2024, Plastipak's direct sales team was instrumental in securing contracts with several Fortune 500 companies, underscoring the effectiveness of this channel for high-value business acquisition.

Plastipak's global manufacturing and distribution network, comprising over 60 facilities by early 2024, acts as a critical channel. This extensive footprint allows for direct production and efficient delivery of plastic packaging solutions to a worldwide customer base.

Leveraging localized production capabilities, Plastipak optimizes its supply chain, ensuring timely and cost-effective product distribution across various continents. This strategic network underpins the company's ability to serve diverse markets effectively.

Plastipak Holdings actively participates in key industry trade shows and conferences, such as NPE: The Plastics Show and Pack Expo International. These events are crucial for showcasing their latest innovations in rigid plastic packaging and connecting with a broad range of potential clients across various sectors. In 2024, Pack Expo International, for instance, drew over 45,000 attendees, offering Plastipak a significant platform to demonstrate their advanced manufacturing capabilities and sustainable packaging solutions.

These gatherings serve as vital channels for direct engagement, allowing Plastipak to present their cutting-edge technologies and build relationships with prospective customers and partners. The networking opportunities at these conferences are invaluable for understanding market trends and reinforcing their position as an industry leader. For example, at the 2024 Global Plastics Summit, Plastipak executives engaged in discussions about circular economy initiatives, highlighting their commitment to sustainability and innovation.

Company Website and Digital Presence

Plastipak's official website and digital presence serve as crucial channels for engaging with stakeholders. These platforms disseminate vital information regarding their extensive product portfolio, innovative services, and commitment to sustainability, including details on their circular economy initiatives. In 2024, the company continued to highlight its advancements in recycled content, with many of its packaging solutions incorporating significant percentages of post-consumer recycled (PCR) materials.

These online resources act as the primary gateway for potential clients to explore Plastipak's capabilities and for existing customers to access support and updates. The company leverages its digital footprint to showcase its global operations and its role in various industries, from food and beverage to personal care. As of early 2024, Plastipak's digital platforms were actively promoting their participation in industry events and their contributions to reducing plastic waste.

- Website Functionality: Serves as a comprehensive information hub for products, services, and corporate news.

- Digital Engagement: Facilitates initial contact and ongoing communication with customers and partners.

- Sustainability Showcase: Highlights Plastipak's environmental initiatives and use of recycled materials, a key focus in 2024.

- Brand Visibility: Reinforces Plastipak's global brand presence and industry leadership.

Customer Referrals and Reputation

Plastipak's decades-long commitment to quality, innovation, and sustainability has cultivated a formidable industry reputation. This strong standing directly translates into a significant volume of customer referrals, as satisfied clients become vocal advocates for the company's products and services.

The trust and credibility earned through consistent performance act as a powerful engine for new business acquisition. Word-of-mouth marketing, amplified by Plastipak's established market presence, consistently opens doors to fresh opportunities, reinforcing its growth trajectory.

- Industry Reputation: Plastipak is recognized for its leadership in rigid plastic packaging solutions.

- Customer Advocacy: Loyal customers frequently recommend Plastipak due to their positive experiences with product quality and service.

- Market Credibility: The company's long-standing presence and commitment to innovation build trust among potential clients.

- Referral Growth: A substantial portion of new business is generated through referrals from existing satisfied customers.

Plastipak's channels are a blend of direct engagement and strategic outreach. Their direct sales force is key for large contracts, while their extensive global manufacturing network ensures efficient delivery. Industry events and a robust digital presence further amplify their reach and showcase innovation.

Customer referrals, fueled by a strong industry reputation for quality and sustainability, also serve as a vital, organic channel for new business acquisition. This multi-faceted approach allows Plastipak to connect with a broad customer base and maintain strong client relationships.

| Channel | Description | 2024 Impact/Data |

|---|---|---|

| Direct Sales Force | Engages directly with large consumer goods and industrial clients for tailored solutions. | Secured contracts with multiple Fortune 500 companies. |

| Global Manufacturing Network | Over 60 facilities by early 2024, enabling localized production and efficient worldwide distribution. | Optimized supply chains for cost-effective delivery across continents. |

| Industry Trade Shows/Conferences | Showcases innovations and connects with potential clients; examples include NPE and Pack Expo. | NPE 2024 featured discussions on circular economy initiatives. Pack Expo International had over 45,000 attendees. |

| Digital Presence (Website) | Provides product information, services, and sustainability updates, highlighting recycled content. | Showcased advancements in post-consumer recycled (PCR) materials in packaging solutions. |

| Customer Referrals | Driven by strong industry reputation and customer advocacy for quality and innovation. | A significant source of new business, reinforcing market credibility. |

Customer Segments

Beverage industry manufacturers, encompassing producers of soft drinks, water, and juices, represent a core customer segment for Plastipak. These companies rely heavily on rigid plastic bottles and containers for their products. In 2024, the global beverage packaging market was valued at over $120 billion, with plastic holding a significant share.

Plastipak's offering of lightweight and increasingly recycled content packaging solutions directly addresses the needs of these beverage giants. For instance, their commitment to incorporating post-consumer recycled (PCR) PET in bottles aligns with the growing consumer demand and regulatory push for sustainable packaging within the beverage sector.

Food product manufacturers represent a significant customer base for Plastipak, encompassing a wide array of sub-sectors such as condiments, dairy, and diverse packaged foods. These companies rely on Plastipak for high-quality, safe, and functional packaging solutions to bring their products to market.

Plastipak supplies essential containers for popular food items like mayonnaise and a broad spectrum of other food products. The demand from this segment is driven by the need for reliable packaging that preserves product integrity and shelf life, while also meeting consumer expectations for convenience and presentation.

A notable trend within this customer segment is the increasing adoption of sustainable packaging. Plastipak is responding to this by emphasizing its rPET (recycled PET) solutions, which offer a more environmentally friendly alternative for food packaging. For instance, the global recycled PET market was valued at approximately $11.2 billion in 2023 and is projected to grow substantially, reflecting this customer demand for sustainable materials.

Personal care and cosmetics brands, including those producing shampoos, lotions, and soaps, represent a significant customer segment for Plastipak. These companies rely on rigid plastic packaging to house their diverse product lines, demanding innovative designs and material options that Plastipak readily provides.

The global personal care market is substantial, with projections indicating continued growth. For instance, the market was valued at approximately $511 billion in 2023 and is expected to reach over $716 billion by 2028, showcasing the sheer volume of products requiring packaging solutions.

Household Chemical and Cleaning Product Companies

Household chemical and cleaning product manufacturers are a key customer base for Plastipak. These companies rely on Plastipak for high-quality, safe, and durable plastic packaging solutions to house their diverse product lines, including detergents, disinfectants, and other cleaning agents. The demand for these products remained robust, with the global household cleaning products market valued at approximately $237.5 billion in 2023 and projected to grow.

Plastipak's offerings cater to the specific needs of this sector, emphasizing chemical resistance and child-resistant features where necessary. The company's ability to provide customized bottle designs and closures ensures product integrity and consumer safety, which are paramount in this industry. In 2024, continued consumer focus on hygiene and home care is expected to sustain demand for these packaging solutions.

- Key Product Needs: Durable, chemically resistant plastic containers and closures for household cleaners and detergents.

- Market Relevance: The global household cleaning products market reached an estimated $237.5 billion in 2023, indicating substantial demand for packaging.

- Safety Features: Emphasis on child-resistant closures and materials that prevent chemical degradation are critical for this segment.

Industrial and Automotive Product Manufacturers

Plastipak's customer base extends to industrial and automotive product manufacturers who rely on specialized rigid plastic containers. These containers are engineered to safely house products such as motor oils, lubricants, and various industrial fluids.

The demands of these sectors necessitate packaging with specific barrier properties to protect contents from degradation and contamination. For instance, the automotive lubricant market alone was valued at approximately $50 billion globally in 2023, highlighting the scale of this segment.

- Specialized Rigid Plastic Containers: For motor oils, lubricants, and industrial fluids.

- Barrier Packaging Requirements: Essential for product integrity and shelf life in demanding applications.

- Market Significance: The automotive lubricant sector underscores the substantial demand for such packaging solutions.

Plastipak serves a diverse range of industries, including food and beverage, personal care, household chemicals, and industrial products. These sectors require robust, safe, and often customized rigid plastic packaging solutions to protect and present their goods effectively.

The company's ability to innovate with materials, such as incorporating post-consumer recycled content, directly addresses evolving market demands for sustainability across these segments. For example, the beverage packaging market, a key area for Plastipak, exceeded $120 billion in 2024.

Key customer needs revolve around packaging integrity, product safety, and increasingly, environmental responsibility. Plastipak's focus on providing solutions that meet these varied requirements solidifies its position as a critical supplier across multiple consumer and industrial markets.

| Customer Segment | Key Needs | Market Relevance (2023/2024 Data) |

|---|---|---|

| Beverage Manufacturers | Rigid plastic bottles, sustainable packaging (PCR PET) | Global beverage packaging market > $120 billion (2024) |

| Food Manufacturers | Safe, functional, sustainable packaging (rPET) | Global rPET market ~$11.2 billion (2023) |

| Personal Care & Cosmetics | Innovative designs, material options | Global personal care market ~$511 billion (2023) |

| Household Chemicals | Durable, chemically resistant, child-resistant closures | Global household cleaning products market ~$237.5 billion (2023) |

| Industrial & Automotive | Specialized barrier properties, robust containers | Automotive lubricant market ~$50 billion globally (2023) |

Cost Structure

Plastipak's cost structure heavily relies on the procurement of raw materials, primarily virgin plastic resins like PET, HDPE, and PP, alongside recycled plastic flakes and pellets. These material purchases represent a substantial portion of the company's overall expenses.

The volatility of commodity prices directly influences these raw material costs. For instance, the price of PET resin can fluctuate significantly based on global supply and demand dynamics, impacting Plastipak's input costs. Efficient sourcing strategies and robust recycling operations are therefore paramount for effective cost management and maintaining profitability.

Plastipak's cost structure is significantly influenced by manufacturing and production overhead, encompassing the operational expenses of its extensive global network of facilities. This includes substantial outlays for energy consumption, which is a critical factor in plastic molding and processing. For instance, in 2024, the global average cost of industrial electricity saw fluctuations, with regions like Europe experiencing higher rates, directly impacting Plastipak's operational costs.

Machinery maintenance and the depreciation of sophisticated manufacturing equipment are also major overhead components. Keeping advanced injection molding machines, blow molding equipment, and automated packaging lines in optimal working condition requires consistent investment in spare parts, skilled technicians, and preventative maintenance programs. The depreciation of these high-value assets over their useful life is a non-cash expense that still impacts profitability.

Factory utilities, such as water, compressed air, and lighting, further contribute to the overhead. Optimizing production efficiency and minimizing energy usage through technological upgrades and process improvements are therefore paramount for Plastipak to effectively manage and control these substantial expenses. For example, implementing variable speed drives on motors can reduce energy consumption by as much as 30% in certain applications.

Plastipak's labor and personnel costs are substantial, encompassing wages, salaries, and benefits for its global workforce. This includes everyone from production line workers to engineers and sales teams.

In 2024, with thousands of employees worldwide, these human capital expenses represent a significant portion of the company's operating budget. Investments in training are also crucial to maintain high standards in manufacturing and innovation.

Research and Development Expenses

Plastipak Holdings invests heavily in research and development, a significant component of its cost structure. These investments are crucial for creating innovative packaging solutions, advancing material science, and developing cutting-edge recycling technologies. For instance, in 2023, the company reported R&D expenses that underscore its commitment to staying ahead in a rapidly evolving market.

These R&D expenditures are not just costs; they are strategic investments aimed at securing a competitive advantage and pioneering sustainable packaging options. By focusing on innovation, Plastipak aims to reduce its environmental footprint and meet growing consumer demand for eco-friendly products.

- Innovation Investment: Significant capital allocated to developing next-generation packaging designs and materials.

- Technology Advancement: Funding for research into advanced recycling processes and material science breakthroughs.

- Competitive Edge: R&D expenses are vital for differentiating Plastipak's offerings and maintaining market leadership.

- Sustainability Focus: A substantial portion of R&D is directed towards creating more sustainable and recyclable packaging solutions.

Logistics and Distribution Costs

Plastipak's logistics and distribution costs are a major component of its overall expenses. These costs encompass the transportation of raw materials like resins to its numerous manufacturing facilities worldwide, as well as the shipment of finished plastic packaging products to a diverse customer base across various industries. In 2024, global freight costs remained a significant factor, influenced by fuel prices and supply chain disruptions, directly impacting Plastipak's bottom line.

Efficiently managing these expenses is critical for maintaining competitive pricing and profitability. This involves optimizing shipping routes, utilizing cost-effective warehousing solutions, and employing sophisticated inventory management systems to minimize holding costs and prevent stockouts. For instance, a substantial portion of Plastipak's operating budget in 2024 was allocated to freight and warehousing, reflecting the global nature of its operations and the volume of goods handled.

- Freight Expenses: Costs associated with ocean, air, and land transportation of raw materials and finished goods.

- Warehousing: Expenses for storing inventory at various strategic locations to ensure timely delivery.

- Inventory Management: Costs related to tracking, managing, and optimizing stock levels across the supply chain.

- Distribution Network Optimization: Investments in technology and strategies to streamline delivery routes and reduce transit times.

Plastipak's cost structure is heavily weighted towards raw material procurement, with virgin and recycled plastic resins forming a significant expense. Manufacturing overhead, including energy consumption and machinery upkeep, also represents a substantial outlay. Labor costs, R&D investments for innovation and sustainability, and logistics for global distribution are further key cost drivers.

| Cost Category | Description | 2024 Impact/Consideration |

|---|---|---|

| Raw Materials | Purchase of PET, HDPE, PP resins and recycled flakes. | Price volatility of virgin resins directly impacts input costs. |

| Manufacturing Overhead | Energy, machinery maintenance, utilities. | Global energy price fluctuations, e.g., higher industrial electricity rates in Europe in 2024, increase operational costs. |

| Labor & Personnel | Wages, salaries, benefits for global workforce. | Significant portion of operating budget; training investments are crucial. |

| Research & Development | Innovation in packaging, recycling tech, material science. | Strategic investment for competitive advantage and sustainability goals. |

| Logistics & Distribution | Transportation of materials and finished goods. | Freight costs influenced by fuel prices and supply chain disruptions in 2024. |

Revenue Streams

Plastipak's core revenue comes from selling rigid plastic containers and preforms. These are the building blocks for many everyday products.

The company generates significant income through high-volume sales to major consumer goods and industrial clients. Think beverage bottles, food packaging, and personal care containers – Plastipak makes many of them.

Customization plays a key role; clients often order specific designs and functionalities, contributing to the revenue mix. For instance, in 2024, the demand for lightweight and sustainable packaging solutions continued to drive innovation and sales in this segment.

Plastipak generates substantial revenue by selling its high-quality recycled resins, specifically rPET and HDPE, to a diverse customer base. This dual approach of supplying internal manufacturing and external clients capitalizes on their advanced recycling infrastructure and the increasing market preference for sustainable packaging solutions.

Plastipak Holdings generates revenue by licensing its proprietary packaging technologies and manufacturing processes to companies worldwide. This strategy allows Plastipak to leverage its extensive intellectual property portfolio, earning income from innovations beyond its own production capabilities.

This licensing model is a significant revenue stream, enabling Plastipak to monetize its R&D investments and maintain a competitive edge in the global packaging market. While specific figures for this segment are not publicly disclosed, Plastipak's consistent innovation in areas like hot-fill PET packaging and barrier technologies underscores the value of this revenue stream.

Design and Engineering Services

Plastipak’s design and engineering services offer a distinct revenue stream beyond just selling packaging. This is particularly true for custom, complex projects handled by their specialized Creative Packaging Studios. For instance, in 2024, the demand for bespoke, high-performance packaging solutions across various sectors like pharmaceuticals and premium consumer goods continued to drive significant revenue from these specialized design engagements.

These services allow Plastipak to leverage their expertise for clients needing highly tailored packaging, often involving intricate geometries, advanced material science, or unique functional requirements. Such projects can command premium pricing, reflecting the intellectual property and specialized labor involved.

- Custom Packaging Design: Fees charged for developing unique packaging concepts and prototypes.

- Engineering Consultation: Revenue generated from providing technical expertise on material selection, manufacturing processes, and product integration.

- Prototyping and Testing: Billing for the creation of physical samples and performance validation.

- Intellectual Property Licensing: Potential revenue from licensing proprietary design elements or technologies.

Sustainability and Circular Economy Solutions

Plastipak's commitment to sustainability and the circular economy directly translates into valuable revenue streams. As consumers and businesses increasingly prioritize eco-friendly options, Plastipak's integrated solutions, such as advanced bottle-to-bottle recycling services, can command premium pricing. This focus on circularity not only meets market demand but also creates a competitive advantage.

The company's ability to offer products with verified lower carbon footprints is a key differentiator. For instance, by investing in technologies that enable the use of higher percentages of recycled content, Plastipak can attract environmentally conscious clients and secure contracts that reward sustainable practices. This aligns with the growing global trend where environmental, social, and governance (ESG) factors heavily influence purchasing decisions.

- Premium Pricing for Recycled Content: Offering bottles with a significant percentage of post-consumer recycled (PCR) material allows for higher price points due to increased demand and the advanced processing required.

- Circular Economy Services: Providing closed-loop recycling systems and collection services generates revenue through processing fees and the sale of recycled materials back into the production cycle.

- Carbon Footprint Reduction as a Service: Quantifying and verifying the reduced carbon footprint of their products can be marketed as a value-added service, attracting clients with their own sustainability targets.

- Partnerships for Sustainability: Collaborating with brands committed to sustainability can lead to long-term supply agreements and co-branded initiatives that drive revenue and brand loyalty.

Plastipak's revenue is primarily driven by the sale of rigid plastic containers and preforms, serving major consumer goods and industrial clients with products like beverage bottles and food packaging. The company also generates income by licensing its proprietary packaging technologies and manufacturing processes globally, capitalizing on its innovation portfolio.

Furthermore, Plastipak earns revenue through custom design and engineering services for specialized packaging projects, reflecting the demand for tailored, high-performance solutions. The company's focus on sustainability also contributes, with premium pricing for products containing recycled content and revenue from circular economy services.

| Revenue Stream | Description | 2024 Relevance |

|---|---|---|

| Rigid Plastic Containers & Preforms | High-volume sales of packaging solutions to CPG and industrial sectors. | Continued demand for lightweight and sustainable options. |

| Technology Licensing | Monetizing proprietary packaging innovations and manufacturing processes. | Leveraging R&D in areas like hot-fill PET and barrier technologies. |

| Custom Design & Engineering | Fees for specialized packaging development and consultation. | Growth in demand for bespoke, high-performance packaging in pharma and premium goods. |

| Recycled Resins & Sustainability Services | Sales of recycled materials (rPET, HDPE) and circular economy solutions. | Premium pricing for PCR content and closed-loop systems driven by ESG focus. |

Business Model Canvas Data Sources

The Plastipak Holdings Business Model Canvas is informed by a blend of internal financial reports, supply chain data, and customer feedback. This comprehensive approach ensures each component accurately reflects operational realities and market positioning.