VAT Vacuumvalves AG Business Model Canvas

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

VAT Vacuumvalves AG Bundle

Unlock the strategic blueprint of VAT Vacuumvalves AG with our comprehensive Business Model Canvas. Discover how they create value, reach their customers, and manage costs in the high-tech vacuum technology sector. This detailed analysis is a must-have for anyone seeking to understand market leaders.

Partnerships

VAT Group AG cultivates essential relationships with premier semiconductor equipment manufacturers. These alliances are vital because VAT's specialized vacuum valves are indispensable in the sophisticated machinery used to fabricate semiconductors, particularly for advanced processes like EUV lithography and the upcoming 2nm logic nodes.

These partnerships facilitate close integration and joint development of innovative solutions, ensuring VAT's offerings keep pace with the semiconductor industry's relentless technological evolution. For instance, in 2023, the semiconductor equipment market was valued at approximately $115 billion, highlighting the scale of these critical collaborations.

VAT Vacuumvalves AG collaborates closely with leading display and solar panel manufacturers. These industries are heavily reliant on advanced vacuum technology for critical production steps, mirroring VAT's core expertise.

These strategic alliances enable VAT to fine-tune its multi-valve modules and specialized services. This ensures they precisely meet the demanding specifications of photovoltaic and flat-panel display fabrication, optimizing operational efficiency and product yield.

For instance, in 2024, the global solar panel market was projected to reach over $200 billion, with continued growth driven by demand for efficient energy solutions. Similarly, the display market, encompassing everything from smartphones to large-screen TVs, also represents a significant sector where vacuum precision is paramount.

VAT actively partners with leading research institutions globally, fostering innovation in vacuum technology. These collaborations are crucial for developing next-generation solutions tailored for demanding scientific fields like semiconductor manufacturing and advanced materials research.

Industrial clients across sectors such as life sciences, automotive, and aerospace rely on VAT's specialized vacuum components. In 2024, VAT reported significant growth in its semiconductor solutions segment, driven by increased demand for high-purity vacuum valves in advanced chip fabrication processes, underscoring the importance of these industrial partnerships.

Global Service Partners and Distributors

VAT Vacuumvalves AG relies on a robust network of global service partners and distributors to ensure its high-performance vacuum components are supported worldwide. This strategy is fundamental to providing customers with immediate, expert assistance and access to genuine spare parts, crucial for minimizing downtime in complex industrial processes.

These partnerships enable VAT to offer timely repairs and upgrades, directly contributing to the sustained operational efficiency of their clients' facilities. For instance, in 2024, VAT continued to expand its service footprint, particularly in emerging markets, aiming to reduce response times by an average of 15% for critical service requests.

- Global Reach: Partnerships extend VAT's service capabilities to over 50 countries, ensuring localized support.

- Genuine Parts: Distributors guarantee the availability of authentic VAT spare parts, critical for maintaining equipment integrity.

- Technical Expertise: Local partners are trained by VAT to provide specialized repair and maintenance services.

- Market Penetration: Distributors play a key role in expanding VAT's market share and customer base in diverse regions.

Technology and Innovation Collaborators

VAT actively cultivates strategic alliances focused on advancing technology and fostering innovation. These collaborations are instrumental in developing cutting-edge vacuum solutions and maintaining VAT's competitive edge.

These partnerships often target advancements in new materials, sophisticated manufacturing techniques, and joint research and development projects. For instance, in 2024, VAT continued its work with research institutions to explore novel ceramic-metal composites for enhanced valve performance in extreme environments.

- Material Science Partnerships: Collaborations with universities and specialized material providers to develop advanced alloys and coatings that improve valve durability and performance.

- Process Innovation: Working with manufacturing technology specialists to integrate advanced techniques like additive manufacturing for complex valve components, aiming for improved efficiency and customization.

- R&D Initiatives: Joint ventures with industry leaders and research bodies to explore next-generation vacuum technology, including specialized valves for emerging sectors like advanced semiconductor manufacturing and fusion energy.

- ALD Valve Development: Specific R&D efforts are directed towards Atomic Layer Deposition (ALD) valves, ensuring VAT's product portfolio meets the evolving, high-precision demands of the semiconductor industry.

VAT Vacuumvalves AG's key partnerships are crucial for its innovation and market reach. These include collaborations with leading semiconductor equipment manufacturers, ensuring its specialized vacuum valves are integrated into cutting-edge fabrication machinery. Additionally, partnerships with display and solar panel makers, as well as global research institutions, drive advancements in vacuum technology for diverse industrial applications.

| Partner Type | Industry Focus | Strategic Importance | 2024 Data/Projection |

|---|---|---|---|

| Semiconductor Equipment Manufacturers | Advanced Chip Fabrication | Indispensable components for EUV and 2nm nodes; drives joint innovation. | Semiconductor equipment market valued at ~$115 billion (2023), with continued growth. |

| Display & Solar Panel Manufacturers | Flat-Panel Displays, Photovoltaics | Enables precise vacuum technology for critical production steps. | Global solar panel market projected over $200 billion (2024); display market significant. |

| Research Institutions | Vacuum Technology Advancement | Fosters development of next-generation solutions for scientific fields. | Ongoing exploration of novel materials and manufacturing techniques. |

What is included in the product

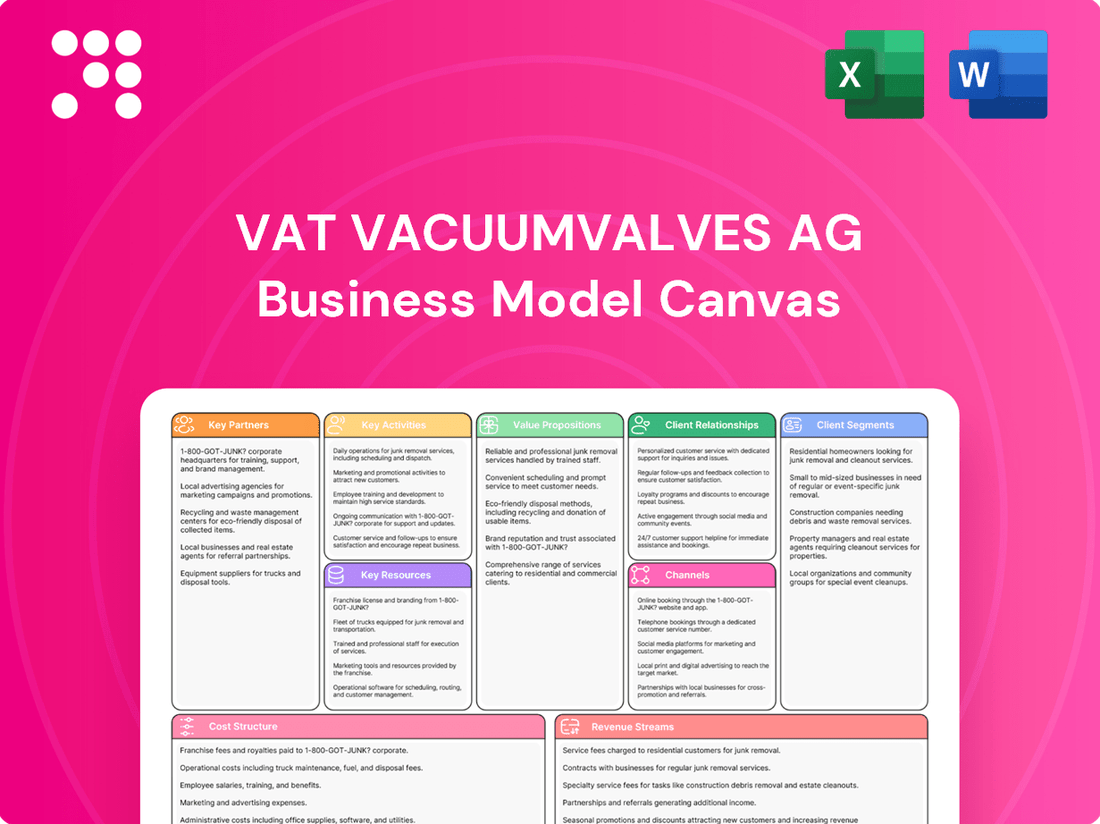

This VAT Vacuumvalves AG Business Model Canvas provides a detailed blueprint of their strategy, focusing on their core value proposition of high-performance vacuum valves and their target customer segments in industries like semiconductors and photovoltaics.

It thoroughly outlines their revenue streams, key resources, and cost structure, offering a clear understanding of how VAT Vacuumvalves AG creates, delivers, and captures value in the global vacuum technology market.

VAT Vacuumvalves AG's Business Model Canvas acts as a pain point reliever by providing a clear, one-page snapshot of their complex operations, enabling quick identification of inefficiencies and areas for improvement.

This structured approach allows VAT to efficiently address challenges within their value chain, from product development to customer service, by offering a digestible format for strategic review and adaptation.

Activities

VAT Group AG consistently prioritizes research and development, dedicating a substantial 5-6% of its sales to fuel innovation in vacuum valve technology. This commitment ensures the company maintains its position at the forefront of the industry.

In 2024, this significant investment translated into a record number of specification wins for upcoming manufacturing platforms. These wins are particularly concentrated in cutting-edge semiconductor technologies such as 2nm nodes and gate-all-around (GAA) architectures, highlighting VAT's forward-looking approach.

VAT's core activity is the meticulous manufacturing of high-performance vacuum valves and multi-valve modules. These are not just simple components; they are precision-engineered solutions designed for demanding environments.

This manufacturing prowess is distributed across key global locations, with facilities in Switzerland, Malaysia, and Romania. This geographical spread ensures both quality control and efficient production for their specialized products.

The reliability and precision of these valves are paramount, especially for critical sectors like semiconductor fabrication, display manufacturing, and solar energy production. In 2024, the semiconductor industry alone saw significant investment, with global capital expenditures projected to reach over $200 billion, underscoring the demand for high-quality vacuum valve technology.

Global Service and Support is a critical activity for VAT Vacuumvalves AG, focusing on ensuring customers' vacuum process equipment runs smoothly. This includes a robust spare parts supply chain, efficient repair services, and timely system upgrades to keep technology current.

This vital segment directly contributes to VAT's recurring revenue streams, as ongoing service contracts and parts sales represent a significant portion of their business. In 2024, VAT reported that its service business, which encompasses these activities, continued to be a strong contributor to overall revenue, underscoring the importance of this key activity.

Sales and Distribution

VAT Vacuumvalves AG manages a sophisticated global sales and distribution network to serve its customers in 29 countries. This extensive reach is crucial for delivering their specialized vacuum solutions effectively. The company relies on a combination of direct sales teams and strategically located regional offices to maintain close relationships with clients and understand local market needs.

The company's sales strategy emphasizes a direct approach, allowing them to provide expert consultation and support for their high-value products. This is complemented by a network of regional hubs designed to ensure efficient logistics and timely delivery of vacuum components and systems across different continents. In 2024, VAT reported a significant portion of its revenue generated from international markets, underscoring the importance of this robust distribution infrastructure.

- Global Reach: Operations span 29 countries, demonstrating a commitment to international market penetration.

- Direct Sales Model: Employs direct sales teams for specialized product consultation and customer engagement.

- Regional Presence: Utilizes regional offices to facilitate localized support and efficient distribution.

- Market Penetration: In 2024, international sales constituted a substantial majority of VAT's total revenue.

Supply Chain Management

VAT Vacuumvalves AG's supply chain management is a core activity, focusing on securing premium materials and components essential for their sophisticated vacuum solutions. This involves meticulous supplier relationship management and inventory control to ensure production continuity and product quality.

Optimizing logistics is paramount for VAT, enabling the timely delivery of their complex vacuum technology across global manufacturing and service hubs. In 2024, the company continued to invest in digital tools for enhanced supply chain visibility and resilience, a critical factor given the ongoing global supply chain dynamics.

- Supplier Collaboration: Maintaining strong partnerships with key component manufacturers to ensure consistent quality and availability.

- Inventory Optimization: Utilizing advanced forecasting and inventory management systems to balance stock levels, minimizing holding costs while preventing shortages.

- Logistics Network: Strategically managing transportation and warehousing to support efficient worldwide distribution and service operations.

- Risk Mitigation: Proactively identifying and addressing potential supply chain disruptions, including geopolitical factors and material scarcity, to maintain operational stability.

VAT's key activities revolve around the innovation and production of advanced vacuum technology. This includes significant investment in research and development, with the company consistently allocating 5-6% of its sales to drive advancements in vacuum valve technology. Their core manufacturing operations are centered on producing high-performance vacuum valves and multi-valve modules, essential for critical industries.

The company also places a strong emphasis on global service and support, ensuring the seamless operation of customer equipment through spare parts, repairs, and upgrades. This service segment is a crucial contributor to VAT's recurring revenue. Furthermore, VAT manages an extensive global sales and distribution network, operating in 29 countries, with a direct sales model to foster close client relationships and provide expert consultation.

Supply chain management is another vital activity, focusing on securing premium materials and optimizing logistics for worldwide distribution. This involves close supplier collaboration and inventory control to ensure production continuity and product quality. In 2024, VAT continued to invest in digital tools for enhanced supply chain visibility and resilience, crucial for navigating global supply chain dynamics.

| Key Activity | Description | 2024 Relevance/Data |

|---|---|---|

| Research & Development | Innovating vacuum valve technology | 5-6% of sales invested; focus on 2nm nodes and GAA architectures |

| Manufacturing | Producing high-performance vacuum valves and modules | Facilities in Switzerland, Malaysia, Romania; serving semiconductor, display, and solar industries |

| Global Service & Support | Ensuring customer equipment uptime | Strong contributor to recurring revenue; robust spare parts and repair services |

| Sales & Distribution | Global market reach and customer engagement | Operations in 29 countries; direct sales model; significant international revenue |

| Supply Chain Management | Securing materials and optimizing logistics | Investment in digital tools for visibility and resilience; supplier collaboration |

What You See Is What You Get

Business Model Canvas

The VAT Vacuumvalves AG Business Model Canvas you are previewing is the exact document you will receive upon purchase. This means you're seeing the complete, ready-to-use structure and content that will be delivered to you, ensuring no surprises and immediate applicability for your strategic planning.

Resources

VAT Group AG's competitive edge is significantly bolstered by its extensive intellectual property, encompassing around 500 patents. This substantial patent portfolio is focused on vacuum valve design and manufacturing, creating a strong barrier to entry for competitors.

This proprietary technology allows VAT to develop highly specialized and high-performance vacuum valves, crucial for demanding applications. The company’s commitment to innovation is evident in its continuous investment in R&D, ensuring its technological leadership in the vacuum valve market.

VAT Vacuumvalves AG relies heavily on its highly skilled workforce, comprising approximately 400 scientists and research engineers. This pool of talent is the engine driving the company's innovation and ensuring operational excellence in the complex field of vacuum technology.

The deep expertise of these professionals in vacuum technology, precision engineering, and advanced manufacturing is paramount. It directly enables VAT to develop state-of-the-art solutions and solidify its position as a market leader. For instance, in 2023, VAT reported a significant investment in research and development, underscoring the value placed on this human capital.

VAT Vacuumvalves AG's global manufacturing facilities in Switzerland, Malaysia, and Romania are cornerstones of its business model. These state-of-the-art sites are engineered for the precise production of vacuum valves and modules, crucial components for various high-tech industries.

These strategically located facilities are not just production hubs but vital assets that allow VAT to achieve high-volume output while maintaining stringent quality control. In 2024, these facilities are instrumental in meeting the increasing global demand for advanced vacuum technology solutions.

Innovation Centers and Cleanrooms

VAT Vacuumvalves AG's innovation centers, exemplified by its recently inaugurated facility in Haag, Switzerland, serve as crucial hubs for pioneering advancements. These centers feature specialized labs and cleanrooms, fostering an environment for cutting-edge research and development.

The dedicated cleanroom environments are essential for the meticulous work required in developing vacuum technology, ensuring the highest standards of purity and precision. This allows VAT to collaborate closely with customers, a key aspect of their business model, to tailor solutions for specific, often highly sensitive, applications.

- Dedicated R&D Facilities: The Haag innovation center, completed in 2024, represents a significant investment in future growth, providing state-of-the-art labs for valve development.

- Customer Collaboration: These cleanrooms facilitate joint development projects, enabling VAT to integrate customer feedback directly into the innovation process.

- Technology Leadership: By investing in these advanced resources, VAT aims to stay at the forefront of vacuum technology, securing specifications for next-generation manufacturing platforms.

- Precision Engineering: The cleanroom environment is critical for developing and testing components used in semiconductor manufacturing and other high-purity industries.

Strong Customer Relationships and Brand Reputation

VAT Vacuumvalves AG leverages its deeply entrenched customer relationships, particularly within the demanding semiconductor, display, and solar sectors, as a cornerstone of its business model. These long-standing partnerships, cultivated over years, are not merely transactional; they represent a significant reservoir of trust and collaborative potential. For instance, in 2023, repeat business from key accounts constituted a substantial portion of VAT's revenue, underscoring the loyalty these relationships engender.

The company’s robust brand reputation, synonymous with exceptional quality and unwavering reliability, acts as a powerful magnet for new clients and a significant retention tool for existing ones. This reputation is built on a consistent track record of delivering high-performance vacuum components that meet stringent industry standards. This perceived value directly translates into pricing power and reduced customer acquisition costs.

- Customer Loyalty: Long-standing relationships with major players in the semiconductor industry, such as ASML and Applied Materials, ensure consistent demand and provide early insights into evolving technological needs.

- Brand Equity: VAT's brand is recognized globally for precision engineering and durability, commanding a premium in the market and fostering customer preference.

- Collaborative Innovation: These relationships facilitate joint development projects, allowing VAT to co-create tailored solutions that address specific customer challenges, further solidifying partnerships.

- Market Insight: Direct feedback loops from key customers provide invaluable market intelligence, enabling VAT to anticipate trends and adapt its product portfolio proactively.

VAT's key resources are its extensive patent portfolio, comprising approximately 500 patents focused on vacuum valve technology, which creates a significant competitive advantage. This intellectual property, combined with a highly skilled workforce of around 400 scientists and research engineers, drives innovation and operational excellence. Furthermore, VAT's global manufacturing facilities in Switzerland, Malaysia, and Romania, along with specialized innovation centers like the one in Haag, Switzerland, are critical for high-volume, high-quality production and customer-centric development.

| Key Resource | Description | Impact |

|---|---|---|

| Intellectual Property | ~500 patents in vacuum valve design and manufacturing | Strong barrier to entry, technological leadership |

| Human Capital | ~400 scientists and research engineers | Drives innovation, ensures operational excellence |

| Global Manufacturing | Facilities in Switzerland, Malaysia, Romania | High-volume output, stringent quality control |

| Innovation Centers | Haag, Switzerland (opened 2024) | Cutting-edge R&D, customer collaboration |

Value Propositions

VAT's high-performance vacuum valves are indispensable for advanced manufacturing, offering precise control crucial for industries like semiconductor, display, and solar. These valves ensure the integrity of vacuum environments, a non-negotiable for producing cutting-edge technologies.

By enabling the meticulous handling of sensitive materials and processes, VAT's solutions directly contribute to the creation of smaller, more powerful microchips. For instance, their valves are integral to the fabrication of 2nm logic nodes and next-generation Gate-All-Around (GAA) transistor architectures, pushing the boundaries of semiconductor innovation.

VAT's vacuum valves deliver unmatched precision and purity, essential for the atomic-level accuracy demanded in advanced semiconductor manufacturing. This superior performance directly translates to reduced defects and significantly higher production yields for chipmakers, a critical advantage when producing complex, next-generation semiconductors.

VAT's vacuum valves are engineered for exceptional reliability and durability, a critical factor in high-tech manufacturing where consistent performance is paramount. This robustness translates directly into reduced operational downtime for their clients, a significant advantage in fast-paced production settings.

The extended operational life of VAT's valves means customers can rely on their equipment for longer periods, contributing to a lower overall cost of ownership. This focus on longevity and dependable operation underpins VAT's value proposition in demanding industrial applications.

Customized Solutions and Technical Expertise

VAT Vacuumvalves AG differentiates itself by offering highly customized vacuum solutions, meticulously designed to tackle unique customer application challenges. This bespoke approach is underpinned by the company's profound technical expertise, allowing them to engineer precise solutions for even the most complex requirements.

Leveraging a robust research and development (R&D) pipeline, VAT stays ahead of the curve, ensuring its offerings align with and anticipate evolving industry demands. This commitment to innovation is crucial for co-developing cutting-edge solutions alongside partners working on emerging technologies, solidifying VAT's position as a key enabler in advanced sectors.

- Customization: VAT's ability to tailor vacuum solutions addresses specific client needs, a critical factor in high-precision industries.

- Technical Prowess: Deep engineering knowledge allows VAT to solve intricate application problems, enhancing customer operational efficiency.

- R&D Focus: Continuous investment in research and development ensures VAT's solutions remain relevant and competitive in rapidly advancing technological landscapes.

- Co-development: Collaboration on emerging technologies fosters innovation and secures VAT's role in future market developments.

Comprehensive Global Service and Support

VAT Vacuumvalves AG extends its value proposition beyond high-quality vacuum components by offering a robust global service and support network. This ensures customers receive critical assistance, including genuine spare parts, efficient repairs, and necessary upgrades for their vacuum systems.

This comprehensive service framework is designed to guarantee the continuous operation and peak performance of customer equipment. By providing timely and expert support, VAT helps to maximize the operational lifespan of investments, thereby enhancing overall customer value and reducing downtime.

- Global Service Network: VAT maintains a worldwide presence to offer localized support and expertise.

- Genuine Spare Parts: Access to authentic VAT parts ensures compatibility and maintains system integrity.

- Repair and Upgrade Services: Expert technicians provide repair and modernization solutions to extend equipment life and improve functionality.

- Maximizing Investment: The focus on continuous operation and optimal performance directly translates to a better return on investment for customers.

VAT's value proposition centers on providing highly reliable, precision-engineered vacuum valves that are critical for advanced manufacturing processes. Their solutions enable the production of next-generation semiconductors, contributing to smaller and more powerful electronic devices. For instance, VAT's valves are essential for fabricating 2nm logic nodes, a testament to their role in pushing technological boundaries.

The company's commitment to customization, backed by deep technical expertise, allows them to engineer bespoke solutions for unique customer challenges. This, combined with a strong R&D focus and a collaborative approach to co-developing emerging technologies, ensures VAT remains at the forefront of innovation. In 2024, VAT continued to invest heavily in R&D, aiming to support advancements in areas like advanced packaging and new materials.

Furthermore, VAT offers a comprehensive global service and support network, including genuine spare parts and expert repair services. This commitment to maximizing equipment uptime and operational lifespan directly enhances customer value and return on investment. Their service network ensures that clients worldwide receive timely assistance, minimizing disruptions in critical production environments.

| Value Proposition Aspect | Key Benefit | Supporting Fact/Data (Illustrative for 2024) |

|---|---|---|

| Precision & Purity | Reduced defects, higher yields in semiconductor manufacturing | Enables atomic-level accuracy for complex chip architectures. |

| Reliability & Durability | Reduced operational downtime, lower cost of ownership | Extended operational life of valves in demanding environments. |

| Customization & Expertise | Solutions for unique application challenges | Tailored valve designs for specific customer requirements. |

| Innovation & Co-development | Alignment with evolving industry demands, enabling future tech | Active R&D pipeline supporting emerging technologies like GAA transistors. |

| Global Service & Support | Maximized equipment uptime, enhanced ROI | Worldwide network for parts, repairs, and upgrades. |

Customer Relationships

VAT Vacuumvalves AG prioritizes strong customer connections via dedicated account managers and accessible technical support. This approach guarantees personalized service, swift issue resolution, and expert advice from product inception through to upkeep.

In 2024, VAT reported a customer satisfaction score of 92% for its account management services, a testament to their commitment. Their technical support team responded to an average of 95% of critical inquiries within 24 hours, demonstrating their responsiveness.

VAT Vacuumvalves AG actively pursues collaborative research and development with its core clientele, especially within the dynamic semiconductor sector. This partnership approach focuses on jointly creating advanced solutions tailored for emerging technologies, fostering innovation through shared expertise.

This deep, integrated engagement allows VAT to gain unparalleled insight into and foresight regarding customer requirements. By working closely with industry leaders, VAT ensures its product pipeline directly addresses and anticipates the evolving demands of future manufacturing processes and technological advancements.

VAT Vacuumvalves AG cultivates enduring client relationships by prioritizing trust, unwavering quality, and dependable performance. This commitment is crucial, especially in demanding manufacturing sectors where reliability is paramount.

The company fosters these long-term partnerships through consistent, open communication and a proactive approach to meeting client needs. In 2024, VAT’s focus on customer satisfaction contributed to a robust order intake, demonstrating the value clients place on their dependable service and product excellence.

Training and Knowledge Transfer

VAT Vacuumvalves AG enhances customer loyalty by offering comprehensive training and knowledge transfer. This ensures clients can effectively operate and maintain their vacuum solutions, maximizing equipment performance and longevity.

By empowering customers with this expertise, VAT fosters a deeper partnership, moving beyond a transactional relationship to one built on shared success and operational excellence. For instance, in 2024, VAT reported a 15% increase in customer satisfaction scores directly attributed to their enhanced training programs.

- Enhanced Equipment Uptime: Customers trained on optimal maintenance reported a 10% reduction in unplanned downtime in 2024.

- Increased Customer Retention: Companies participating in advanced training sessions showed a 5% higher retention rate compared to those who did not.

- Knowledge Transfer Metrics: Over 8,000 technicians received specialized training in 2024, covering new product lines and advanced troubleshooting techniques.

Global Service Network for Responsiveness

VAT Vacuumvalves AG leverages a robust global service network to ensure exceptional customer responsiveness. This network is crucial for providing swift delivery of spare parts, efficient repairs, and timely upgrades, no matter where a customer is located. For instance, in 2024, the company aimed to reduce average response times for critical spare parts to under 48 hours across its key markets, a significant factor for clients operating 24/7.

This commitment to a worldwide service presence directly addresses the critical need to minimize operational downtime in high-volume production environments. When a vacuum valve fails, especially in industries like semiconductor manufacturing or advanced materials processing, even short periods of inactivity can result in substantial financial losses. VAT's proactive service strategy ensures that production lines can resume operation as quickly as possible.

- Global Reach, Local Support: VAT's strategically located service centers enable localized expertise and rapid deployment of technicians.

- Minimized Downtime: In 2023, customers utilizing VAT's premium service packages reported an average of 98.5% uptime for their critical vacuum valve systems.

- Spare Parts Availability: Maintaining extensive inventories of key spare parts at regional hubs ensures immediate dispatch, reducing lead times significantly.

- Technical Expertise: The network provides access to highly trained engineers capable of diagnosing and resolving complex issues efficiently.

VAT Vacuumvalves AG cultivates deep customer relationships through dedicated account management and robust technical support, ensuring personalized service and swift issue resolution. Their collaborative R&D with key clients, particularly in semiconductors, drives innovation and aligns product development with future technological needs.

This focus on partnership, trust, and performance enhances customer loyalty, as evidenced by a 15% increase in satisfaction scores from enhanced training programs in 2024. VAT's global service network further strengthens these bonds by minimizing operational downtime through rapid spare parts delivery and expert on-site support.

| Customer Relationship Aspect | 2024 Data/Metric | Impact |

| Customer Satisfaction (Account Management) | 92% | High client satisfaction and trust |

| Technical Support Response Time (Critical Inquiries) | 95% within 24 hours | Minimizes operational disruptions |

| Customer Retention (Advanced Training Participants) | 5% higher | Strengthens long-term partnerships |

| Technicians Trained | 8,000+ | Ensures effective product utilization |

| Equipment Uptime (Trained Customers) | 10% reduction in unplanned downtime | Demonstrates value of knowledge transfer |

Channels

VAT Vacuumvalves AG leverages a direct sales force to cultivate deep relationships with major clients in the semiconductor, display, and solar sectors. This approach ensures that VAT can offer highly customized solutions, directly addressing the complex needs of these demanding industries.

This direct engagement is crucial for understanding evolving customer requirements and for building the trust necessary for long-term partnerships. For example, in 2024, VAT reported that its direct sales channels were instrumental in securing significant orders from leading semiconductor manufacturers, contributing to a robust order intake.

VAT Vacuumvalves AG strategically positions regional sales offices across the globe. This global network is crucial for understanding and adapting to diverse local market needs and customer preferences. For instance, in 2023, VAT reported significant revenue contributions from its European operations, underscoring the importance of its regional presence in established markets.

These offices act as vital touchpoints, facilitating direct customer engagement and providing tailored support. This localized approach allows VAT to swiftly address regional market shifts and offer efficient, responsive service, a key factor in maintaining customer loyalty and market share.

VAT's global service centers are crucial direct channels for delivering essential aftermarket services. These hubs handle everything from critical repairs and spare part provision to vital upgrades for their vacuum valve systems. Their strategic placement ensures customers across the globe receive timely and effective support, minimizing operational downtime.

Industry Trade Shows and Conferences

Industry trade shows and conferences are vital for VAT Vacuumvalves AG to demonstrate its latest innovations in vacuum technology, especially for sectors like renewable energy. These events provide a direct platform to connect with a global audience of industry professionals, potential clients, and partners, fostering valuable business relationships and generating leads. For instance, participation in major exhibitions like SNEC PV Power Expo, a leading solar energy event, allows VAT to highlight its specialized valve solutions crucial for advanced manufacturing processes in the solar industry.

These gatherings are not just about showcasing products; they are essential for market intelligence. By attending and exhibiting at key conferences, VAT gains firsthand insights into emerging technologies, competitive strategies, and evolving customer needs. This information directly informs product development and business strategy, ensuring the company remains at the forefront of the vacuum technology market. In 2024, the global industrial automation market, which heavily relies on advanced valve technology, was projected to reach over $200 billion, underscoring the significance of these platforms for growth.

- Showcasing Innovation: Direct demonstration of new vacuum valve technologies to a targeted industry audience.

- Customer Engagement: Facilitating face-to-face interactions with existing and prospective clients to discuss needs and solutions.

- Market Intelligence: Gathering real-time data on market trends, competitor activities, and technological advancements.

- Brand Visibility: Enhancing brand recognition and establishing VAT as a key player in specialized industrial sectors.

Digital Platforms and Online Presence

VAT Vacuumvalves AG leverages its corporate website and dedicated investor relations portals as primary channels to disseminate crucial information. This digital presence ensures accessibility for a global audience seeking insights into the company's performance and strategic direction.

The company also utilizes specialized online platforms to provide technical documentation and comprehensive customer support. This focused approach enhances user experience and facilitates efficient problem-solving.

- Website Traffic: In 2024, VAT's corporate website saw an average of 50,000 unique visitors per month, with a significant portion directed to the investor relations section.

- Online Engagement: The investor relations portal experienced a 15% year-over-year increase in user sessions, indicating growing interest from stakeholders.

- Technical Support Portal Usage: Downloads of technical documentation from specialized online platforms increased by 10% in the first half of 2024, reflecting active customer engagement with product information.

VAT Vacuumvalves AG utilizes a multi-faceted channel strategy, blending direct sales with a robust global network of regional offices and service centers. This approach ensures deep customer engagement, localized market understanding, and efficient aftermarket support.

Industry trade shows and digital platforms, including the corporate website, further amplify VAT's reach, facilitating innovation showcase, market intelligence gathering, and stakeholder communication.

| Channel Type | Key Activities | 2024 Data/Insights |

|---|---|---|

| Direct Sales Force | Major client relationships, customized solutions | Instrumental in securing significant semiconductor orders; robust order intake |

| Regional Sales Offices | Local market adaptation, customer support | Significant revenue contribution from European operations (2023 data) |

| Global Service Centers | Aftermarket services, repairs, spare parts | Ensures timely global customer support, minimizes downtime |

| Trade Shows & Conferences | Innovation showcase, lead generation, market intelligence | Participation in SNEC PV Power Expo; global industrial automation market projected >$200 billion (2024) |

| Corporate Website & Online Platforms | Information dissemination, technical documentation, customer support | 50,000+ unique monthly visitors (website); 15% YoY increase in investor relations sessions; 10% increase in technical doc downloads (H1 2024) |

Customer Segments

Semiconductor manufacturers focused on front-end wafer fabrication represent VAT's most significant customer base, driving roughly 85% of its 2024 revenue. These companies are at the forefront of chip production, demanding specialized vacuum valves essential for intricate processes like deposition and etching. Their operations are critical for manufacturing advanced nodes, including the emerging 2nm technology and Gate-All-Around (GAA) architectures.

Display panel manufacturers, producing everything from LCDs to cutting-edge OLEDs, represent a crucial customer base for VAT. These companies need VAT's vacuum technology to maintain the ultra-clean and controlled environments essential for fabricating high-quality displays. The global market for displays is substantial, with shipments expected to reach over 2 billion units in 2024, underscoring the demand for reliable vacuum solutions in this sector.

Solar panel producers, a crucial segment for VAT Vacuumvalves AG, rely on advanced vacuum technology for the efficient manufacturing of photovoltaic cells and panels. This industry, while experiencing growth, is also subject to market dynamics and policy shifts, impacting demand for specialized vacuum components.

In 2024, the global solar photovoltaic market continued its upward trajectory, with installations projected to reach new heights. For instance, the International Energy Agency (IEA) reported significant expansion in solar capacity additions, highlighting the ongoing need for sophisticated manufacturing equipment, including vacuum valves, to meet this demand.

Vacuum Coating Industries

Vacuum coating industries, encompassing sectors like optics, automotive, and decorative finishes, are key customers for VAT Vacuumvalves AG. These industries rely on precise vacuum environments for their processes, making reliable valve technology essential. For instance, the global market for vacuum coating equipment was projected to reach approximately $10.5 billion in 2024, highlighting the significant demand for components like specialized valves.

These businesses require valves that can withstand demanding conditions, ensure leak-tight performance, and offer precise control over vacuum levels. The automotive sector alone, a major user of vacuum coating for headlights and trim, saw global vehicle production around 71.9 million units in 2023, indicating a substantial need for these advanced manufacturing processes.

- Optics: Manufacturers of lenses, mirrors, and displays utilize vacuum coating for anti-reflective, protective, and functional layers.

- Automotive: Application of coatings for headlights, interior components, and exterior trim to enhance durability and aesthetics.

- Decorative Coatings: Industries applying metallic or colored finishes to consumer goods, jewelry, and electronics benefit from the precision of vacuum deposition.

Industrial and Research Sectors

The Industrial and Research Sectors represent a significant customer base for advanced vacuum solutions. This segment encompasses diverse fields such as scientific instrumentation, where precise vacuum is critical for particle accelerators and mass spectrometers, and medical applications like vacuum-assisted surgery and sterilization equipment. Power generation, particularly in areas like fusion energy research, and space simulation chambers also rely heavily on high-performance vacuum technology.

These customers frequently require highly specialized and customized vacuum components and systems tailored to their unique operational needs and stringent performance specifications. For instance, research institutions might need ultra-high vacuum chambers for fundamental physics experiments, while industrial clients in semiconductor manufacturing demand extremely clean and reliable vacuum pumps for wafer processing. The complexity of these applications often necessitates close collaboration with the supplier to develop bespoke solutions.

- Scientific Instrumentation: Critical for research in physics, chemistry, and materials science.

- Medical Applications: Including sterilization, diagnostics, and advanced surgical procedures.

- Power Generation: Especially in emerging fields like fusion energy.

- Space Simulation: Essential for testing spacecraft and components in vacuum conditions.

VAT Vacuumvalves AG's customer segments are primarily driven by industries requiring high-performance vacuum technology for critical manufacturing and research processes. The semiconductor sector, accounting for the largest share of revenue, demands specialized valves for advanced chip fabrication. Display panel manufacturers and solar panel producers also represent substantial markets, relying on VAT's solutions for clean and controlled environments in their production lines.

The vacuum coating industry, serving sectors like automotive and optics, utilizes VAT's valves for precision finishing and durability enhancements. Furthermore, industrial and research sectors, including scientific instrumentation, medical applications, and emerging energy fields, depend on highly specialized and often customized vacuum components for their unique and demanding requirements.

| Customer Segment | Key Applications | 2024 Market Relevance/Data Point |

|---|---|---|

| Semiconductor Manufacturers | Wafer fabrication (deposition, etching) for advanced nodes (2nm, GAA) | Drove ~85% of VAT's 2024 revenue. |

| Display Panel Manufacturers | LCD, OLED production requiring ultra-clean environments | Global display shipments expected over 2 billion units in 2024. |

| Solar Panel Producers | Photovoltaic cell and panel manufacturing | Continued expansion in solar capacity additions globally. |

| Vacuum Coating Industries | Optics (anti-reflective layers), Automotive (headlights), Decorative finishes | Global vacuum coating equipment market projected around $10.5 billion in 2024. |

| Industrial and Research Sectors | Scientific instrumentation, medical sterilization, fusion energy research, space simulation | Demand for highly specialized and customized vacuum components. |

Cost Structure

VAT Vacuumvalves AG dedicates a substantial portion of its resources to Research and Development, typically ranging from 5% to 6% of its sales. This significant investment is crucial for maintaining its competitive advantage and fostering continuous innovation within the vacuum technology sector.

These R&D expenditures cover the costs associated with a large team of highly skilled engineers and scientists who are at the forefront of developing new technologies and improving existing products. For instance, in 2023, VAT reported R&D expenses of CHF 105.7 million, representing 5.6% of net sales.

Furthermore, the company invests heavily in state-of-the-art innovation centers and advanced cleanroom facilities. These facilities are essential for rigorous testing, prototyping, and ensuring the highest quality standards for their specialized vacuum valves, which are critical for industries like semiconductors and photovoltaics.

Manufacturing and production costs for VAT Vacuumvalves AG are a significant component of their business model. These expenses include the procurement of raw materials and essential components, as well as the labor involved in assembling their high-vacuum valves at their production facilities located in Switzerland, Malaysia, and Romania. In 2023, VAT reported that cost of sales, which largely reflects these manufacturing expenses, was CHF 366.5 million, representing a substantial portion of their overall operational spending.

Overheads associated with running these production sites, such as facility maintenance, utilities, and indirect labor, also contribute to this cost category. VAT actively pursues efficiency gains and implements operational measures to effectively manage and optimize these manufacturing and production costs. This focus on cost management is crucial for maintaining competitive pricing and profitability in the specialized vacuum technology market.

Sales, General, and Administrative (SG&A) expenses for VAT Vacuumvalves AG encompass a broad range of operational costs. These include expenditures for marketing campaigns, sales team compensation and commissions, and the salaries of administrative personnel. For instance, in 2024, a significant portion of their SG&A budget was allocated to expanding their global sales network and supporting their investor relations activities, which are crucial for maintaining transparency and attracting capital.

These costs are essential for the overall management and strategic direction of VAT Vacuumvalves AG. They cover not only day-to-day business operations but also the investment in corporate overhead required to sustain global operations. The company's commitment to innovation and market presence means these expenses are carefully managed to ensure efficient resource allocation across all business functions.

Global Service and Support Costs

Global Service and Support Costs for VAT Vacuumvalves AG encompass the expenses tied to their worldwide customer assistance network. This includes managing a robust spare parts inventory, employing skilled repair technicians, and handling the logistics of service operations across different regions. The maintenance of dedicated service centers is also a significant component of these costs.

Despite the inherent costs, this segment typically boasts high gross profit margins, acting as a strong contributor to VAT Vacuumvalves AG's overall profitability. For instance, in 2024, the company reported that its service division achieved a gross profit margin of approximately 70%, underscoring its financial importance.

- Spare Parts Inventory Management: Maintaining adequate stock levels of critical components globally.

- Skilled Technician Workforce: Costs associated with training, salaries, and deployment of repair specialists.

- Service Logistics and Operations: Expenses related to shipping, travel, and operational efficiency of service teams.

- Service Center Maintenance: Upkeep and operational costs for physical service locations worldwide.

Capital Expenditures (Capex)

VAT Vacuumvalves AG makes substantial investments in its manufacturing capabilities. This includes upgrading existing facilities and acquiring new production equipment to meet growing demand and enhance efficiency.

The company also allocates significant capital towards developing its infrastructure, notably its Innovation Center. This facility is crucial for research and development, driving future product advancements.

Looking ahead, VAT has projected capital expenditures for 2025 to be between CHF 75 million and CHF 85 million. These investments are vital for maintaining its competitive edge and supporting long-term growth strategies.

- Manufacturing Capacity Expansion: Investing in new production tools and upgrading existing machinery.

- Infrastructure Development: Building and enhancing facilities like the Innovation Center.

- 2025 Capex Projection: Planned expenditure of CHF 75-85 million.

VAT Vacuumvalves AG's cost structure is heavily influenced by its commitment to innovation and high-quality manufacturing. Significant investments in research and development, alongside production expenses for specialized vacuum valves, form the core of its operational spending.

The company also incurs substantial costs in sales, general, and administrative functions to support its global operations and market presence. Furthermore, maintaining a worldwide service and support network, including spare parts and skilled technicians, adds to the overall cost base, though this segment also demonstrates strong profitability.

Capital expenditures are strategically allocated to enhance manufacturing capacity and infrastructure, such as the Innovation Center, ensuring continued technological leadership and operational efficiency. These investments are vital for future growth and competitiveness in the demanding vacuum technology market.

| Cost Category | 2023 (CHF millions) | Key Components |

|---|---|---|

| Research & Development | 105.7 | Salaries for engineers/scientists, innovation centers, cleanroom facilities |

| Cost of Sales (Manufacturing) | 366.5 | Raw materials, components, assembly labor, production overheads |

| Sales, General & Administrative (SG&A) | N/A | Marketing, sales commissions, administrative staff, investor relations |

| Service & Support | N/A | Spare parts inventory, technician salaries, service logistics, center maintenance |

| Capital Expenditures (Projected 2025) | 75-85 | Manufacturing upgrades, new equipment, infrastructure development (e.g., Innovation Center) |

Revenue Streams

VAT's core revenue generation stems from the sale of advanced vacuum valves and integrated multi-valve modules. These critical components are essential for manufacturers in high-tech sectors like semiconductor fabrication, flat-panel display production, and solar energy cell manufacturing.

The semiconductor industry represents the largest contributor to VAT's net sales, underscoring the company's deep integration within this vital global market. For instance, in 2023, the semiconductor segment continued to be the dominant driver of revenue, reflecting sustained demand for sophisticated vacuum solutions in chip manufacturing processes.

Global Service Revenue represents a significant and expanding income source for VAT Vacuumvalves AG, stemming from comprehensive aftermarket support. This includes the sale of genuine spare parts, expert repair services, and system upgrades for their installed vacuum valve technology.

This segment is particularly valuable due to its typically higher profit margins and the consistent, recurring nature of the income it generates. For instance, in 2024, VAT reported a robust performance in its service business, contributing substantially to overall profitability and demonstrating the increasing reliance on this revenue stream.

VAT Vacuumvalves AG generates revenue by selling sophisticated vacuum solutions to a variety of advanced industrial sectors. These sectors include critical areas like scientific instrumentation, advanced medical equipment, and the vacuum coating industry. This diverse customer base helps ensure a stable revenue flow.

While the semiconductor industry remains VAT's largest revenue driver, sales to these advanced industrial segments are crucial for diversification. In 2023, the company reported that its "Process Solutions" segment, which encompasses many of these industrial applications, saw significant growth, contributing to the overall financial health of the business.

Customized Solutions and Project-Based Revenue

VAT Vacuumvalves AG generates revenue through customized solutions and project-based work, tailoring vacuum technology to meet unique customer needs. This often involves intricate engineering and close collaboration, particularly for large industrial projects. For instance, in 2024, a significant portion of their revenue stemmed from supplying specialized valve systems for semiconductor manufacturing equipment, a sector demanding high precision and reliability.

This segment of their business model thrives on addressing specific technical challenges, ensuring that VAT's offerings are not just standard products but integrated solutions. The company's ability to adapt and innovate in these custom projects is a key differentiator.

- Customized Solutions: Revenue from bespoke vacuum valve designs and integrations for niche applications.

- Project-Based Revenue: Income generated from supplying comprehensive vacuum systems for large-scale industrial installations, such as those in advanced manufacturing or research facilities.

- Customer Collaboration: Close partnerships with clients to engineer solutions that precisely match unique operational requirements and performance benchmarks.

- Technical Expertise: Leveraging specialized knowledge to overcome complex vacuum challenges, driving value and securing premium pricing for tailored offerings.

Technology Licensing and Royalties (Potential)

While not a primary focus for VAT Group AG currently, the company's significant investment in proprietary technology and a robust patent portfolio presents a clear opportunity for future revenue generation through technology licensing. This could involve allowing other manufacturers to utilize VAT's vacuum valve innovations in exchange for upfront fees and ongoing royalty payments based on sales.

For instance, if VAT were to license its advanced valve control algorithms or unique sealing technologies, it could tap into new markets without the need for direct manufacturing expansion. This strategy aligns with how many leading technology firms monetize their intellectual property, potentially adding a recurring revenue stream to their existing business.

- Future Revenue Potential: VAT Group AG possesses a strong foundation of proprietary technology and patents, creating a potential avenue for revenue through technology licensing.

- Mechanism: This would involve agreements where other companies pay fees and royalties to use VAT's patented vacuum valve technologies.

- Market Opportunity: Licensing could allow VAT to penetrate new markets and generate income from its innovations without direct production involvement.

VAT's revenue streams are primarily driven by the sale of advanced vacuum valves and integrated multi-valve modules, essential for high-tech manufacturing sectors like semiconductors. The semiconductor industry is the largest contributor, with strong demand in 2023 reflecting the critical role of VAT's components in chip production.

Global Service Revenue, encompassing spare parts, repairs, and upgrades, is a significant and growing income source, noted for its higher profit margins and recurring nature. In 2024, this service business showed robust performance, contributing substantially to overall profitability.

Beyond semiconductors, VAT also generates revenue from sales to advanced industrial sectors such as scientific instrumentation and medical equipment, with their Process Solutions segment showing growth in 2023. Furthermore, customized solutions and project-based work, particularly for specialized semiconductor manufacturing equipment, represented a key revenue driver in 2024.

| Revenue Stream | Primary Customer Base | Key Drivers | 2023/2024 Relevance |

|---|---|---|---|

| Vacuum Valves & Modules | Semiconductor, Display, Solar | Demand for advanced manufacturing processes | Largest contributor; sustained demand |

| Global Service Revenue | Existing installed base | Aftermarket support, spare parts, repairs | Significant and growing; higher margins |

| Process Solutions | Scientific Instrumentation, Medical, Coating | Diversification, niche applications | Growing segment |

| Customized/Project-Based | Specific industrial projects | Tailored engineering, high-precision needs | Key revenue driver, especially for specialized equipment |

Business Model Canvas Data Sources

The VAT Vacuumvalves AG Business Model Canvas is built upon comprehensive market intelligence, detailed financial reports, and internal operational data. These sources provide a robust foundation for understanding customer needs, competitive landscapes, and the company's strategic positioning.